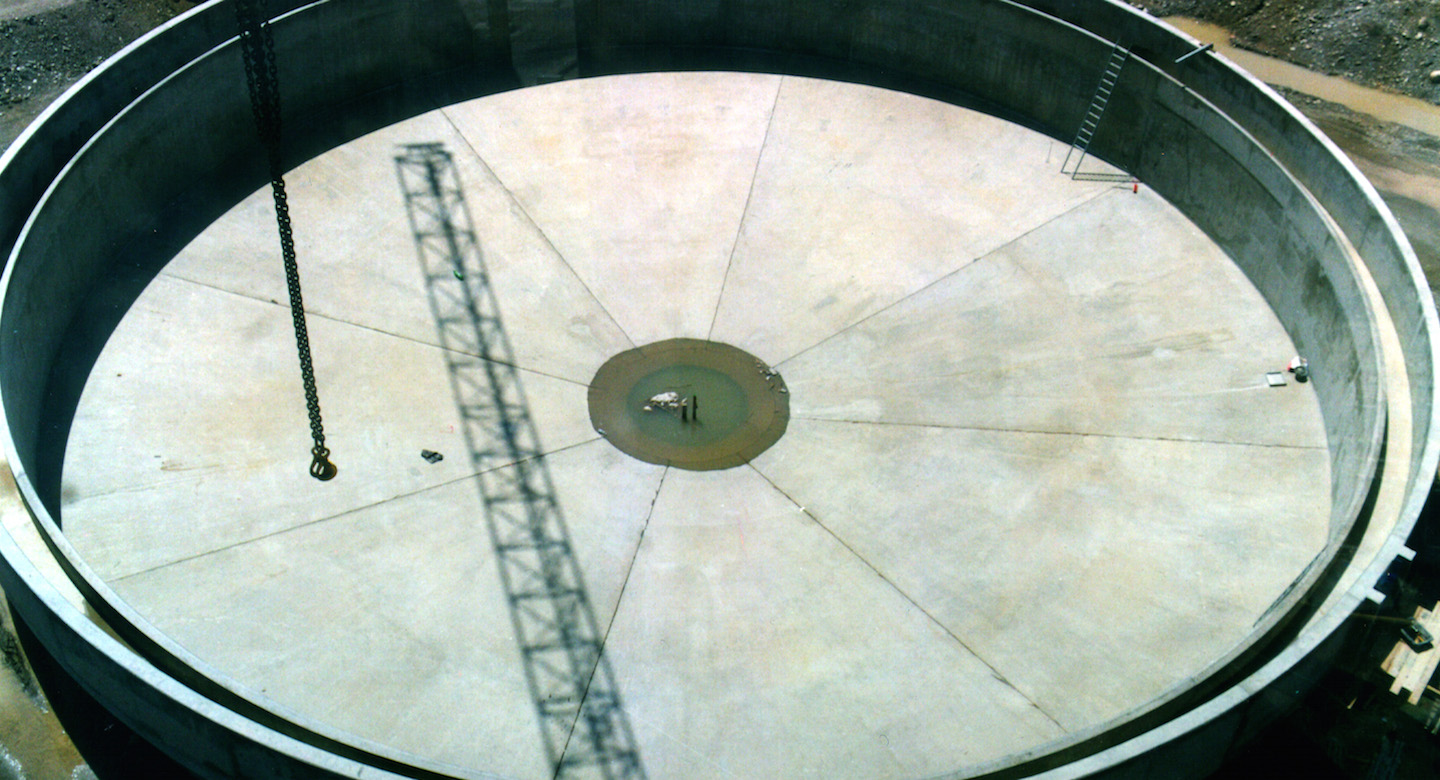

This project aims to build a 190,000 m³ liquefied natural gas (LNG) reservoir in the United Kingdom.

Located on the Isle of Grain – England’s east coast, 60 km from London – this project is part of the program to expand the capacity of Europe’s largest LNG terminal. This «full integrity» tank has an internal tank made of 9% nickel steel and an external enclosure made of prestressed concrete poured in place using slip forms.

Reconciliar a los londinenses con un Támesis saneado constituye un desafío estructural para la capital británica. VINCI Construction Grands Projets contribuye a ello gracias al diseño y construcción de un colector de aguas pluviales y residuales entre la estación de bombeo de Abbey Mills y Beckton: el Lee Tunnel.

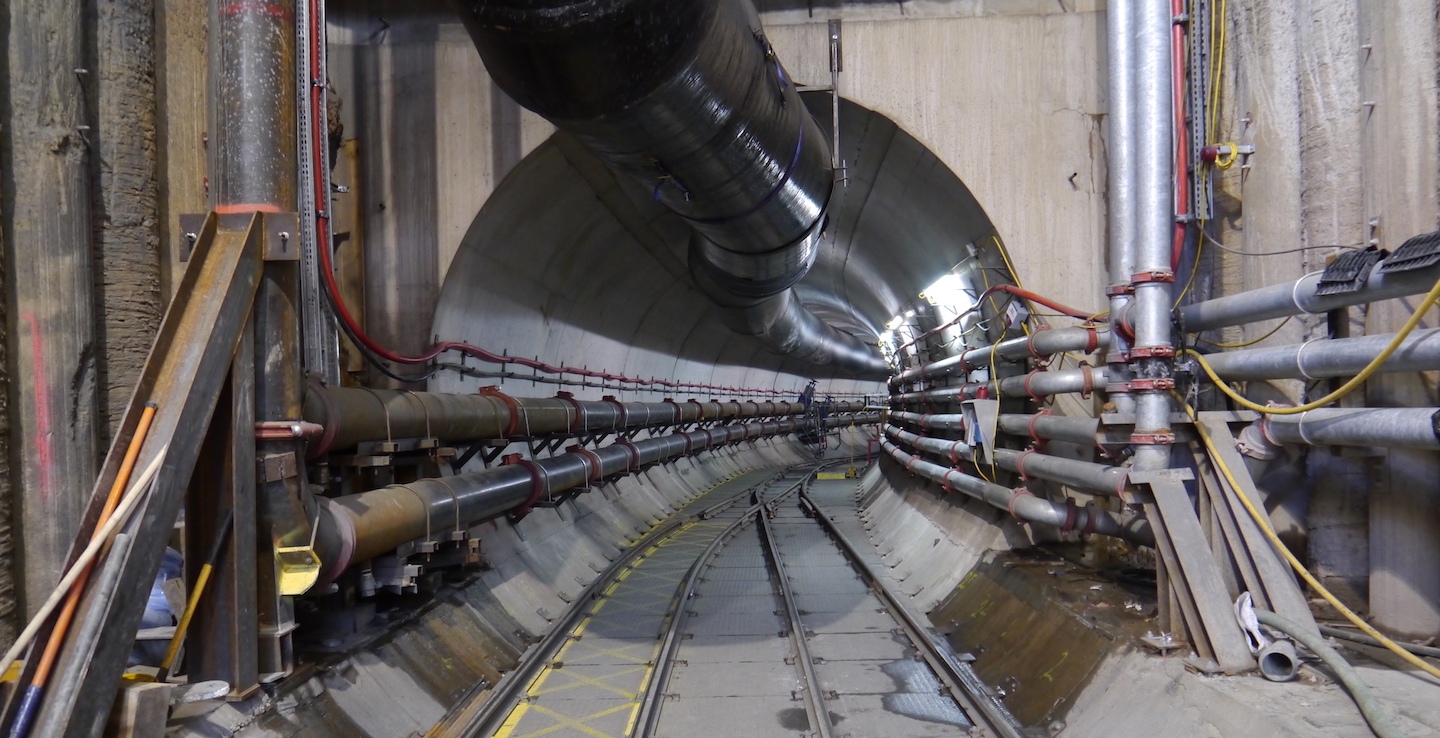

El proyecto abarca la construcción de una galería de 6,9 kilómetros de longitud y 7,2 metros de diámetro interno. Situado a una profundidad de hasta 80 metros, permitirá reducir a la mitad los 32 millones de m3 de aguas residuales que se vierten al Támesis cada año, capturándolas en su origen.

The Tideway Scheme consists of designing and building a system for wastewater and stormwater transfer and storage in central London. No less than 32 kilometres of tunnels will be necessary to increase the capacity of the existing network. This ambitious project aims to intercept wastewater and stormwater and divert them into treatment plants to prevent effluents into the River Thames. VINCI Construction Grands Projets, in a joint venture with Costain Limited, and Bachy Soletanche Ltd have been invited to participate in the construction of the East works package, one of the three making up the Tideway project. This package will connect Chambers Wharf and the Abbey Mills Pumping Station where the Lee Tunnel starts in East London. It consists of the design and construction of two tunnel sections: a main 5.5-km tunnel and a connecting 4.6-km tunnel.

Socio desde hace casi 17 años de la National Water Commission, VINCI Construction Grands Projets participa en proyectos que permiten mejorar las condiciones de acceso al agua para la población jamaicana en la mayor parte del territorio: en las parroquias noroccidentales de las isla, en Negril, Lucea y Montego Bay para los sistemas de producción y distribución de agua potable o, incluso en Kingston, para Constant Spring, Seaview Mona & Hope para la rehabilitación de las plantas de tratamiento, así como Falmouth y Ocho Ríos, en Port Antonio para una red urbana mixta (agua potable, aguas residuales y drenaje) y, por último, en las plantas de tratamiento de aguas residuales de Boscobel y Elletson Flats. Hemos participado en todas las etapas del ciclo del agua ofreciendo soluciones flexibles y adaptadas a nuestro Cliente y al contexto local. Desde la captación del agua bruta en los ríos o capas freáticas, pasando por diversos métodos de tratamientos, almacenamiento, suministro y distribución a los consumidores, así como la gestión de la red y del sistema de facturación del agua, hasta su depuración para su devolución al medio natural, VINCI Construction Grands Projets ha trabajado en el 80% del agua producida en la isla.

Tras el éxito del Lee Tunnel en la recogida de aguas pluviales y aguas residuales, Scottish Water, operador público de las redes de distribución de agua en Escocia, le encargó a un consorcio, del que VINCI Construction Grands Projets formaba parte, el diseño y construcción del túnel de Shieldhall.

La obra consistió en la construcción de 2 pozos de 20 metros de profundidad y 15 metros de diámetro, de una zanja cubierta de 250 metros de longitud y de un túnel de 5 kilómetros de longitud (con un diámetro interior de 4,7 metros).

In order to supply the City of Faisalabad with drinking water, we were mandated by Pakistan’s Water and Sanitation Agency to increase drinking-water production capacity, renovate, improve, and expand the supply and distribution network, and optimize network performance. As part of a public utility project to supply an entire section of the city with water, this new treatment plant is designed to operate 24/7.

Situado en el extremo de la península verde de Little Island, en la localidad de Carrigrenan, en la desembocadura del río Lee y a 15 kilómetros al este de Cork, la planta de tratamiento de aguas residuales y reciclado de lodos de Cork, concebida en la actualidad para una población de 250.000 habitantes, constituye el primer eslabón de la red de alcantarillado de la ciudad irlandesa.

VINCI Construction Grands Projets se hizo cargo de la dirección de la ingeniería civil que incluía 16 tanques hidráulicos y 10 cámaras de transferencia de hormigón, 7 edificios, 23.000 m3 de hormigón y 3.800 toneladas de acero. La planta entró en servicio en enero de 2004.

As part of developments north of the city of Doha, the capital of Qatar, a consortium consisting of VINCI Construction Grands Projets, QDVC, and Entrepose Contracting was entrusted with the task of building the largest wastewater-pumping station in the Gulf States. The structure was designed to collect, raise, and convey wastewater from North Doha to a plant located some 20 kilometres to the north in the desert. The project included construction of a wastewater-pumping station with a capacity of 900,000 cubic metres a day as well as the supply and installation of pipes.

In 2011, ONEAD (Djibouti’s national water and sewerage authority) awarded a contract to VINCI Construction Grands Projets to rehabilitate and expand the drinking-water supply network in Djibouti. The project consisted in rehabilitating 36 wells, carrying out network segmentation by district, repairing leaks in defective equipment, installing 100 kilometres of HDPE pipes, and providing 2,000 connections. Following this initial phase and the client’s satisfaction, we were hired once again in 2015:

For the second phase which consisted of rehabilitating the drinking-water network and expanding it by 36 kilometres, building a semi-underground storage tank, and providing no fewer than 3,000 connections. This phase was designed to improve access to water in working-class neighbourhoods and newly developed urban areas.

For another contract for a project that was complementary to the second phase of the initial project; it consisted in expanding the main water-supply network by 25 kilometres, upgrading three water towers, implementing a telemetry system for the drinking-water segment of the network, and – on the sanitation side – rehabilitating 3 STEP and the open-air drainage channel.

Yemen’s National Water and Sanitation Authority mandated us to build a wastewater treatment plant with a capacity of 50,000 m³/day in the capital city of Sana’a. The project, located north of the capital city next to El Rahaba International Airport, included construction of an underground intake wastewater pipeline made of fibreglass that is 6 kilometres long and ranges in diameter from 1,200 to 1,500 millimetres, civil engineering for the filtration plant, construction of a 200,000-m³ storage pond for wastewater designed for irrigation purposes, and implementation of about 3 kilometres of cast-iron or fibreglass pipes ranging in diameter from 80 to 1,500 millimetres. The treatment plant includes a workshop, a back-up power station (4 MW), and an administrative building.