CONTEXTE

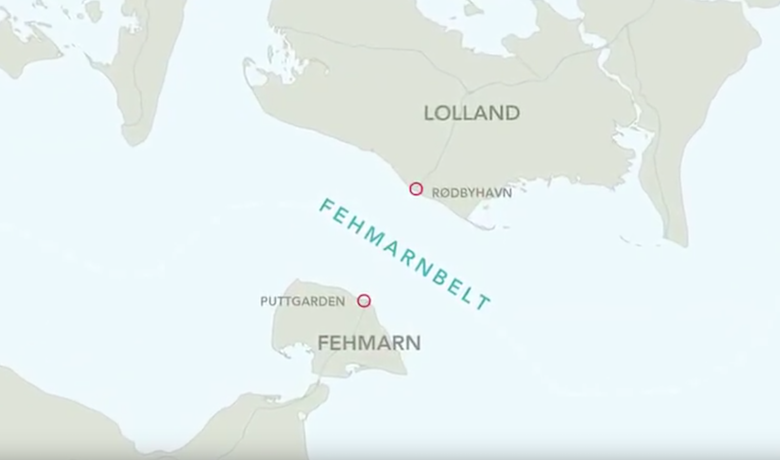

In 1995, during construction of the Øresund tunnel, which connects Denmark with the Scandinavian peninsula, the Danish government made a commitment to the Swedish government to promote the development of a fixed link between Denmark and Germany, which would also benefit Sweden. However, Germany, in the midst of reconstruction, quickly indicated its lack of interest in this scheme. In 2008, following a long period of discussion, authorities in both countries signed a treaty based on Danish funding to build the crossing. Subsequently, German authorities would be responsible for linking the structure to their country’s roadway network. As a result of this agreement, feasibility studies on possible solutions, either an immersed tunnel or a bridge, got under way.

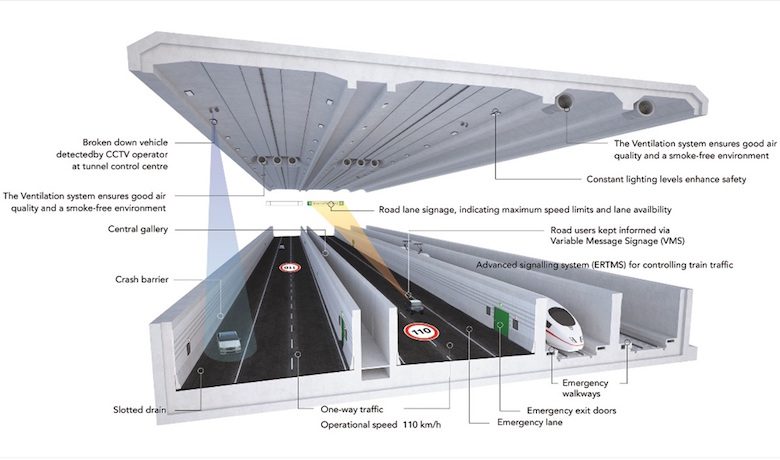

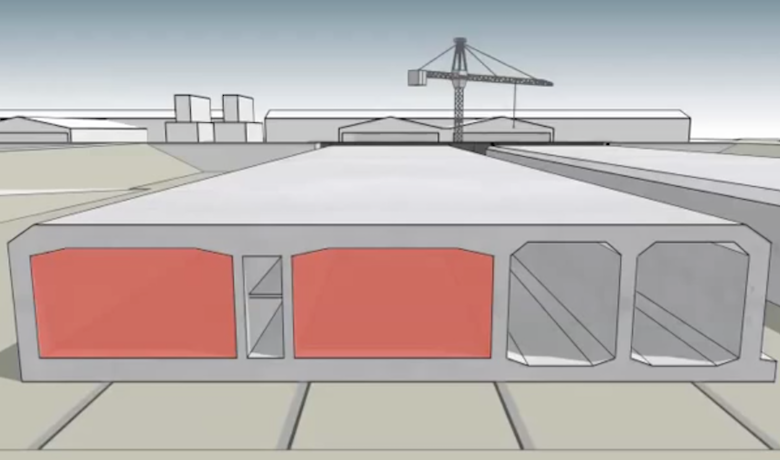

In 2011, a decision was made to build an immersed tunnel. The call for tenders was issued.

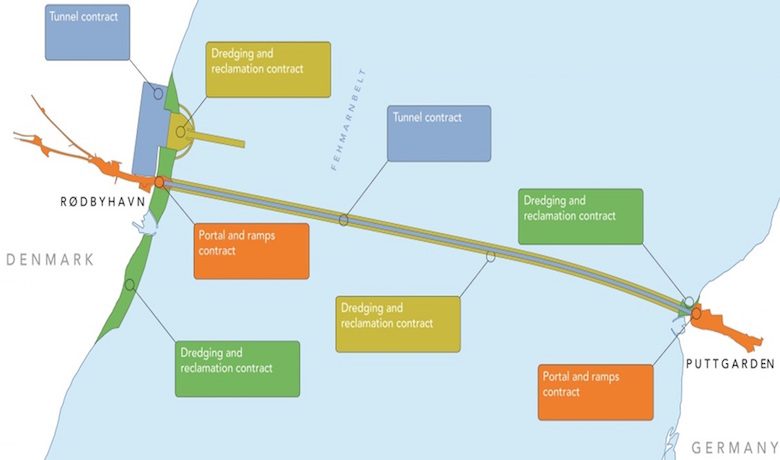

On March 4, 2016, our consortium was awarded contracts for the three work packages for which we had presented our candidacy. On May 30, 2016 in Copenhagen, the three contracts were officially signed.