Representatives from the donors countries coming from all around the world, Petro Porochenko the President of Ukraine, Xavier Huillard the Chairman & CEO of VINCI and Pierre Heilbronn Vice-President of EBRD together with the NOVARKA teams (50% VINCI Construction Grands Projets, leader, and 50% Bouygues Travaux Publics) celebrated the end of the sliding operation of the New Safe Confinement over the damaged reactor. This technical achievement marks an historical day for Chernobyl.

[Replay] To watch the ceremony: https://www.youtube.com/watch?v=Z_jPEzJaI0c

To know more:

(Photo credits: Francis Vigouroux – Photo libraries of VINCI and subsidiaries. All rights reserved.)

The end of the sliding operation is an historical progress and an exceptional technical achievement. It will be celebrated in Chernobyl on 29 November 2016 with the highest Ukrainian authorities representatives, Xavier Huillard Chairman & CEO of VINCI and the EBRD Vice-President Pierre Heilbronn attending.

You can watch a live streaming of this ceremony on VINCI Construction’s YouTube Channel.

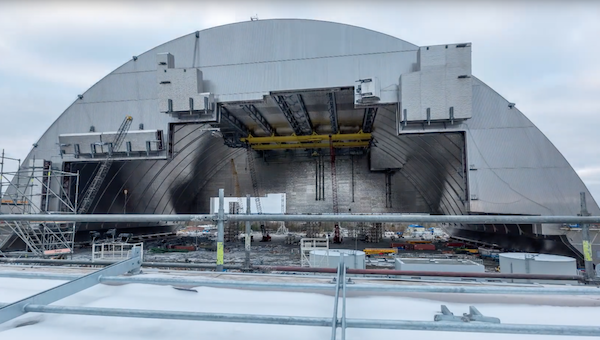

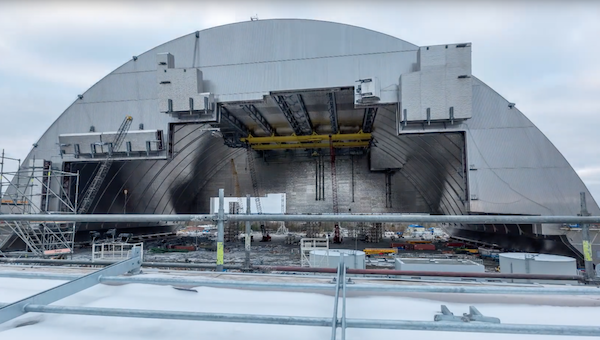

The Chernobyl damaged reactor is now safely confined thanks to the work and dedication of the 10,000 employees of NOVARKA (50% VINCI Construction Grands Projets, leader, and 50% Bouygues Travaux Publics) since the contract was signed in 2007. This project, stemming from the international ideas contest launched by Ukraine in 1992 and won by Campenon Bernard SGE (which later became VINCI Construction Grands Projets), allows both confinement and dismantling of the damaged reactor thanks to remote controlled tools installed inside the arch. The New safe Confinement has been built in front of the reactor, in a cleaned area, and then slid over 327 meters since the beginning of November 2016.

We’ve just completed the most important sliding operation ever done in the world, moving the biggest metallic structure (36,200 tonnes which can cover the Stade de France and whose weight is 3,5 times the weight of Eiffel Tower).

2017 will be dedicated to installation of the membranes to hermetically seal the arch over the damaged reactor, and to test the dismantling systems. The hand over is scheduled at the end of 2017.

[LIVE] You can watch a live streaming of Chernobyl reactor number 4 confinement ceremony on VINCI Construction’s YouTube Channel with the following link: https://www.youtube.com/watch?v=Z_jPEzJaI0c

The ceremony starts at 12 noon in Chernobyl, i.e. 11am in Paris and 10am GMT.

Chernobyl’s New Safe Confinement (NSC) is the largest moveable land-based structure ever built, with a span of 257 metres, a length of 162 metres, a height of 108 metres and a total weight of 36,000 tonnes equipped.

It will now be moved into its resting place over Chernobyl’s reactor 4 which was destroyed in the accident 30 years ago.

The sliding is done with help of a special skidding system that consists of 224 hydraulic jacks to push the arch 60 centimetres each stroke. It is anticipated that the total skid time will be around 40 hours of operation spread over a period of up to 5 days.

The NSC was constructed in a clean area near reactor 4 of the Chernobyl Nuclear Power Plant and will be slid over 327 metres to seal off the unit. It will make the site safe and allow for the eventual dismantling of the aging shelter currently housing the reactor and the management of the radioactive waste within the structure.

Ostap Semerak, Minister of Ecology and Natural Resources of Ukraine, said: “The start of the sliding of the Arch over reactor 4 at the Chernobyl NPP is the beginning of the end of a 30-year long fight with the consequences of the 1986 accident. The credit for construction of this one-of-a-kind technological structure goes to an expert team of engineers and builders. This is a historic step towards the improvement of environmental safety throughout the world, as well as in the Chernobyl exclusion zone. And it has only become possible thanks to immense international support. The fact that more than 40 contributing countries and donor countries united around the goal of protecting humanity from the radioactive consequences of the tragedy is another demonstration that environmental safety remains a priority for global policymakers. And I believe that the transformation of the exclusion zone into a safe area will demonstrate the change in Ukraine’s overall environmental policy, too.”

Igor Gramotkin, Director General of the Chernobyl Nuclear Power Plant, commented: “For us the arch is not just 36.000 tonnes of prefabricated metal. It is 36.000 tonnes of our belief in success, of trust in our site, our people and in Ukraine.”

Vince Novak, EBRD Director, Nuclear Safety, added: “This is the culmination of many years of hard work by Ukraine and the international community. The New Safe Confinement project would not have been possible without the support of the over 40 donor countries who are contributors to the Chernobyl Shelter Fund. The new structure illustrates what is possible in a spirit of determined and coordinated joint effort and thanks to the generous support of EBRD shareholders.” Nicolas Caille, project director for Novarka – the French construction consortium formed by VINCI Construction and Bouygues Construction – said: “This is a one-of-a-kind project serving the aims of the Ukrainian authorities. We are immensely proud of what we together with our partners have achieved. The New Safe Confinement shows what is technically possible. At the same time, given the circumstances, we must all hope that never again will a similar structure have to be built on the site of a nuclear accident and in a contaminated environment.”

The construction of the New Safe Confinement by Novarka started in 2012 after extensive preparatory works on the ground. Because of its vast dimensions the structure had to be built in two halves which were lifted and successfully joined together in 2015. The arch-shaped structure is fitted with an overhead crane to allow for the future dismantling of the existing shelter and the remains of reactor 4. The New Safe Confinement has a lifespan of at least100 years and will cost €1.5 billion.

Continuing its work with the Mandarin Oriental Group, VINCI Construction Grands Projets, in partnership with Petit (VINCI Construction France), signed the contract to renovate the Mandarin Oriental Hyde Park hotel in London, a project with a value of about £60 million (€69 million).

Following a one-year PCSA (Pre-Construction Services Agreement) period, the VINCI Construction teams, working for the first time under the PLENDI brand, will be responsible for renovating all rooms and public areas in the hotel.

The 12,000 m² refurbishment will be carried out in two nine-month phases. The first phase will cover all rooms in the Knightsbridge wing; the second phase the rooms overlooking Hyde Park.

Two large 165 m² penthouse suites with an exceptional view of the park will be built as an extension on the 9th floor roof. The hotel will remain open with reduced inventory throughout the works.

For the third year in a row, Groupe Moniteur organised BIM d’Or, an event that rewards the best BIM and digital modelling initiatives by French companies. After being listed, our project to renovate the five-star Mandarin Oriental Hotel in London was awarded a prize at the ceremony held on September 19.

In what way was the BIM process deployed in this project an innovation? In this complex project – prestigious establishment with stringent requirements, heritage building with an intricate layout and structure, work on a busy site, and other challenges – BIM deployment facilitated technical validation and enabled painstaking and comprehensive spatial coordination. As a result, the teams were able to look forward to a major reduction in uncertainty during the construction phase thanks to streamlined management of timetables and the flow of people coming and going, particularly on the client’s side.

In all, 31 out of 130 projects were listed, including 8 VINCI projects. Among the 10 prizewinners, VINCI Construction Grands Projets joined VINCI Facilities, winner of the project of the year prize (BIM d’Or in the Operations/Maintenance category) and VINCI Autoroutes, winner in the Infrastructure category. View the complete list of prizewinners here (in French).

The construction works, the addition of 65 kilometers of third lanes and the construction of 2 kilometers of 4 bidirectional tunnels, are estimated to last 5 years and will be carried out by a joint-venture consisting of VINCI Construction Grands Projets / VINCI Construction Terrassement (50%) and Conconcreto (50%). The whole infrastructure will be operated and maintained by the concessionaire, formed by VINCI Highways (50%), Constructora Conconcreto (25%) and Industrial Conconcreto (25%).

In July 2015, VINCI has announced a strategic partnership with Constructora Conconcreto, a leading Colombian construction and real estate development company. The partnership involves VINCI’s acquisition of a 20% stake in Constructora Conconcreto via a reserved capital increase. VINCI’s ambition is to put down long-term roots in Colombia, one of the most dynamic countries in South America. For about a decade, the country has regularly recorded annual GDP growth in excess of 4%. The construction sector is particularly promising, with volume expected to increase by 5% annually in coming years.

This new package (number 1122), worth €45 million, calls for 700 metres of blast-tunnelling in 45 months right in the city centre.

VINCI Construction Grands has already contributed to this construction project with package number 1103. On November 11 at 11:11 AM, VINCI Construction Grands Projets celebrated with MTR by opening a blasted tunnel section at the Hon Keng site.

The Group presents its subsidaries’ expertises & projects: Entrepose, Sogea-Satom, Soletanche Bachy/Menard and VINCI Construction Grands Projets. Take a look at our offer in the mining activities: from concept to start-up, our comprehensive construction offer.

“I have just learned that Pierre Berger passed away suddenly last night. On behalf of the VINCI Group and in a personal capacity, I wish to extend my heartfelt condolences to Pierre’s family and friends and to the 70,000 Eiffage employees. As he demonstrated during the years he spent with the VINCI Group, Pierre was a man of exceptional energy who was driven by a passion for our business activities that is the hallmark of an outstanding leader.”

You can go to www.vinci-construction-projects-plant4sale.com. (available in French, English and Spanish languages) and look for plant or equipment with a search engine tool detecting key word, kind of plant or manufacturer’s brand. The current location of the equipment and its number of hours of use are mentioned in the classified advertisements. You will find there as well the contact details of our Plant & Equipment Division for further information.