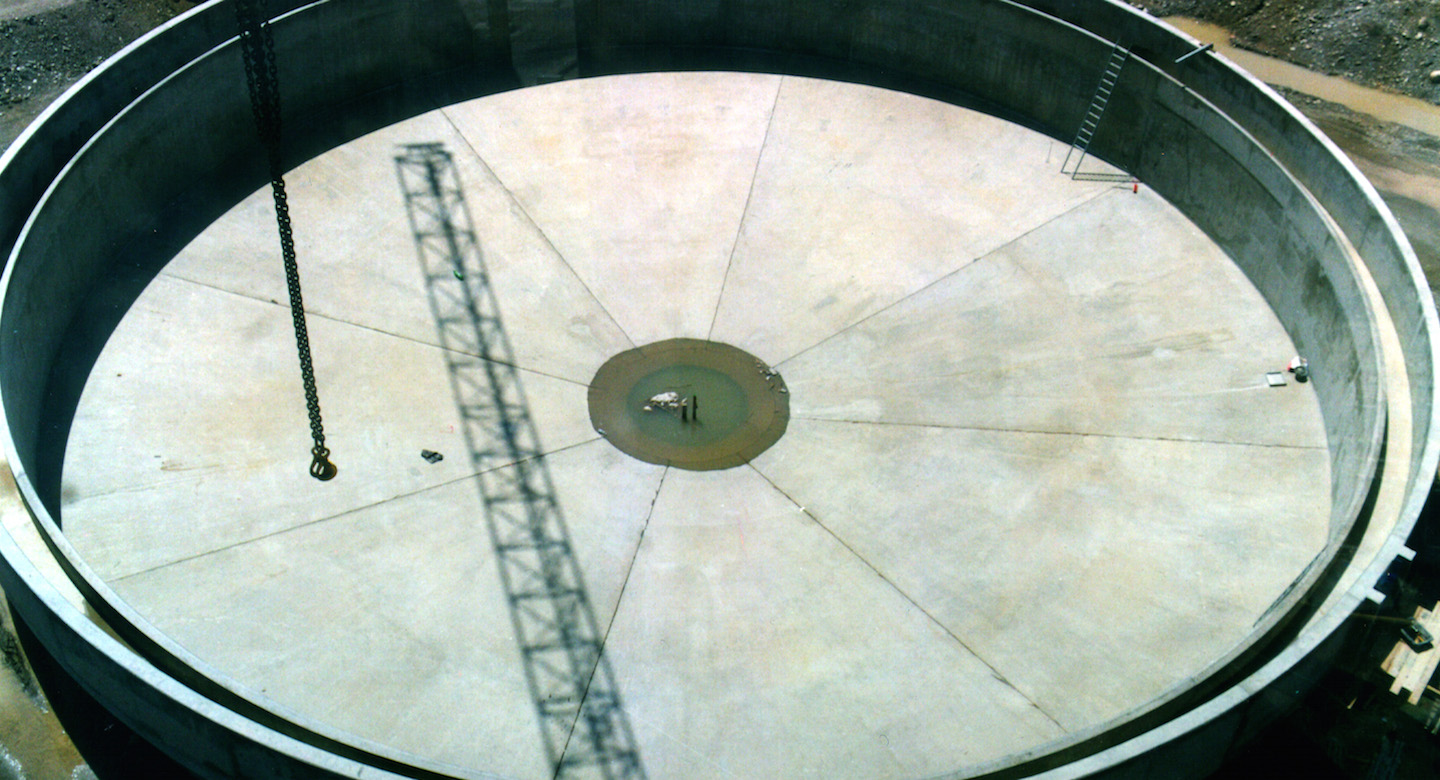

This project aims to build a 190,000 m³ liquefied natural gas (LNG) reservoir in the United Kingdom.

Located on the Isle of Grain – England’s east coast, 60 km from London – this project is part of the program to expand the capacity of Europe’s largest LNG terminal. This “full integrity” tank has an internal tank made of 9% nickel steel and an external enclosure made of prestressed concrete poured in place using slip forms.

The Tideway Scheme consists of designing and building a system for wastewater and stormwater transfer and storage in central London. No less than 32 kilometres of tunnels will be necessary to increase the capacity of the existing network. This ambitious project aims to intercept wastewater and stormwater and divert them into treatment plants to prevent effluents into the River Thames.

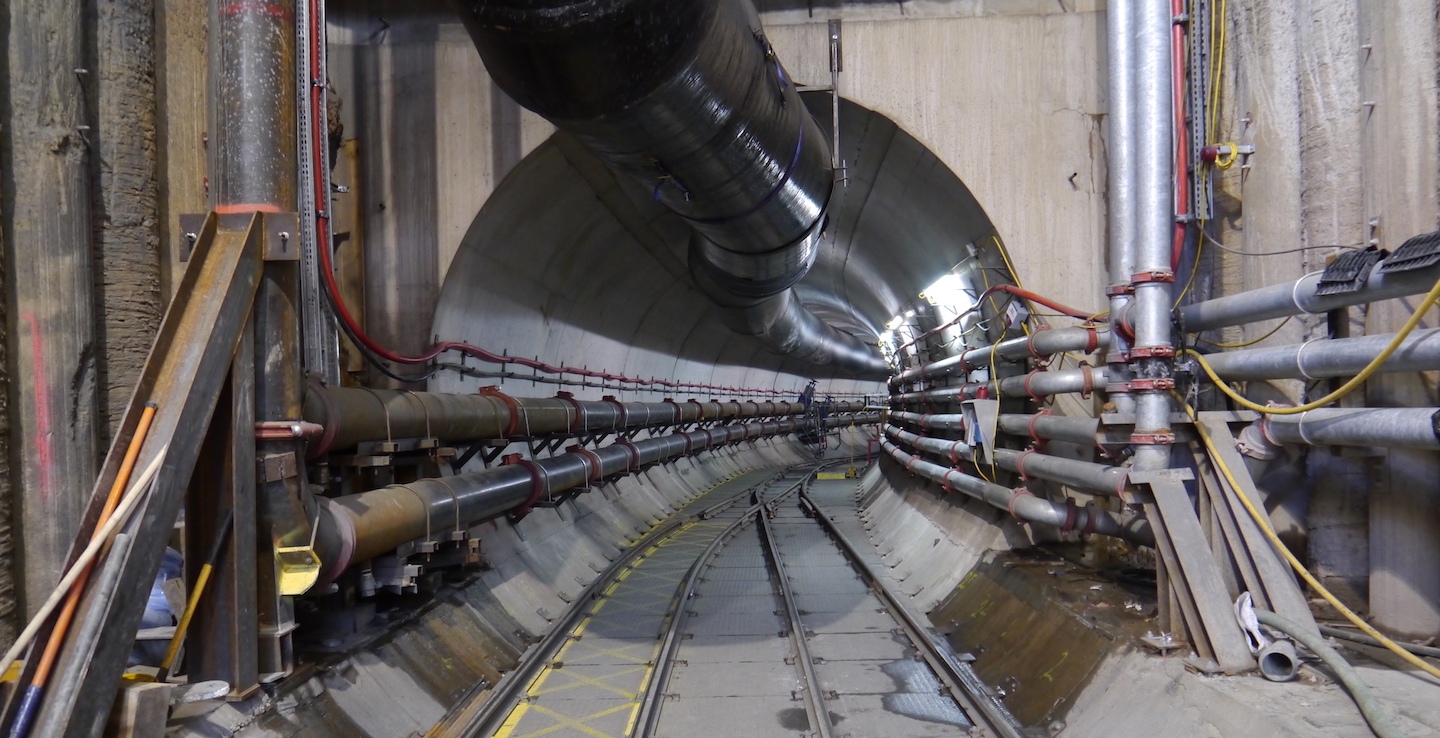

VINCI Construction Grands Projets, in a joint venture with Costain Limited, and Bachy Soletanche Ltd have been invited to participate in the construction of the East works package, one of the three making up the Tideway project. This package will connect Chambers Wharf and the Abbey Mills Pumping Station where the Lee Tunnel starts in East London. It consists of the design and construction of two tunnel sections: a main 5.5-km tunnel and a connecting 4.6-km tunnel.

In its 17-year partnership with the National Water Commission, VINCI Construction Grands Projets has been active on projects designed to provide people in Jamaica with improved access to water resources over much of the island, including the northwest parishes, in Negril, Lucea, and Montego Bay for drinking-water production and distribution systems, in Kingston for Constant Spring, Seaview Mona & Hope and in Falmouth and Ocho Rios for treatment-plant upgrades, at Port Antonio for a multi-use urban network (drinking water, wastewater, and drainage), and for wastewater treatment plants at Boscobel and Elletson Flats. We provide services at all stages of the water-management cycle, including modular solutions that meet specific client and local needs. VINCI Construction Grands Projets has had a hand in no less than 80% of Jamaica’s water production, including raw river water and groundwater table intake, various treatment processes, storage, supply, and distribution to consumers, along with water-network management, invoicing systems for consumer use, and water purification prior to its return to the environment.

Following our success on the Lee Tunnel project (waste- and stormwater collection in London), Scottish Water, which runs the public water-management network in that country, entrusted a consortium that included VINCI Construction Grands Projets with the design-build mandate for the Shieldhall Tunnel.

The project consists in the construction of 2 shafts 20 metres deep and 15 metres in diameter, a cut-and-cover trench 250 metres long, and a tunnel 5 kilometres long (with an interior diameter of 4.7 metres).

The Cork wastewater treatment and mud-recycling plant, located at Carrigrenan at the very tip of the verdant Little Island peninsula at the mouth of the Lee River and 15 kilometres east of Cork, was upgraded to serve a population of 250,000. The plant is the final component in the city’s water-sanitation network. VINCI Construction Grands Projets led the civil-engineering mandate that includes 16 hydraulic storage tanks, 10 reinforced-concrete transfer chambers, 7 buildings, 23,000 m3 of concrete, and 3,800 tonnes of steel. The plant was opened in January 2004.

Reconciling Londoners with a cleaner River Thames – that was a key challenge for the British capital. VINCI Construction Grands Projets contributed to this endeavour with a design-build project for a stormwater and sewage collection system between the Abbey Mills and Beckton pumping stations: the Lee Tunnel. The project called for the construction of a tunnel 6.9 kilometres long with an internal diameter of 7.2 metres. Located at a depth reaching 80 metres, it will reduce by half the 32 million cubic metres of wastewater poured into the Thames every year by collecting it at the source.

In order to supply the City of Faisalabad with drinking water, we were mandated by Pakistan’s Water and Sanitation Agency to increase drinking-water production capacity, renovate, improve, and expand the supply and distribution network, and optimize network performance. As part of a public utility project to supply an entire section of the city with water, this new treatment plant is designed to operate 24/7.

As part of developments north of the city of Doha, the capital of Qatar, a consortium consisting of VINCI Construction Grands Projets, QDVC, and Entrepose Contracting was entrusted with the task of building the largest wastewater-pumping station in the Gulf States. The structure was designed to collect, raise, and convey wastewater from North Doha to a plant located some 20 kilometres to the north in the desert. The project included construction of a wastewater-pumping station with a capacity of 900,000 cubic metres a day as well as the supply and installation of pipes.

In 2011, ONEAD (Djibouti’s national water and sewerage authority) awarded a contract to VINCI Construction Grands Projets to rehabilitate and expand the drinking-water supply network in Djibouti. The project consisted in rehabilitating 36 wells, carrying out network segmentation by district, repairing leaks in defective equipment, installing 100 kilometres of HDPE pipes, and providing 2,000 connections. Following this initial phase and the client’s satisfaction, we were hired once again in 2015:

For the second phase which consisted of rehabilitating the drinking-water network and expanding it by 36 kilometres, building a semi-underground storage tank, and providing no fewer than 3,000 connections. This phase was designed to improve access to water in working-class neighbourhoods and newly developed urban areas.

For another contract for a project that was complementary to the second phase of the initial project; it consisted in expanding the main water-supply network by 25 kilometres, upgrading three water towers, implementing a telemetry system for the drinking-water segment of the network, and – on the sanitation side – rehabilitating 3 STEP and the open-air drainage channel.

Yemen’s National Water and Sanitation Authority mandated us to build a wastewater treatment plant with a capacity of 50,000 m³/day in the capital city of Sana’a. The project, located north of the capital city next to El Rahaba International Airport, included construction of an underground intake wastewater pipeline made of fibreglass that is 6 kilometres long and ranges in diameter from 1,200 to 1,500 millimetres, civil engineering for the filtration plant, construction of a 200,000-m³ storage pond for wastewater designed for irrigation purposes, and implementation of about 3 kilometres of cast-iron or fibreglass pipes ranging in diameter from 80 to 1,500 millimetres. The treatment plant includes a workshop, a back-up power station (4 MW), and an administrative building.