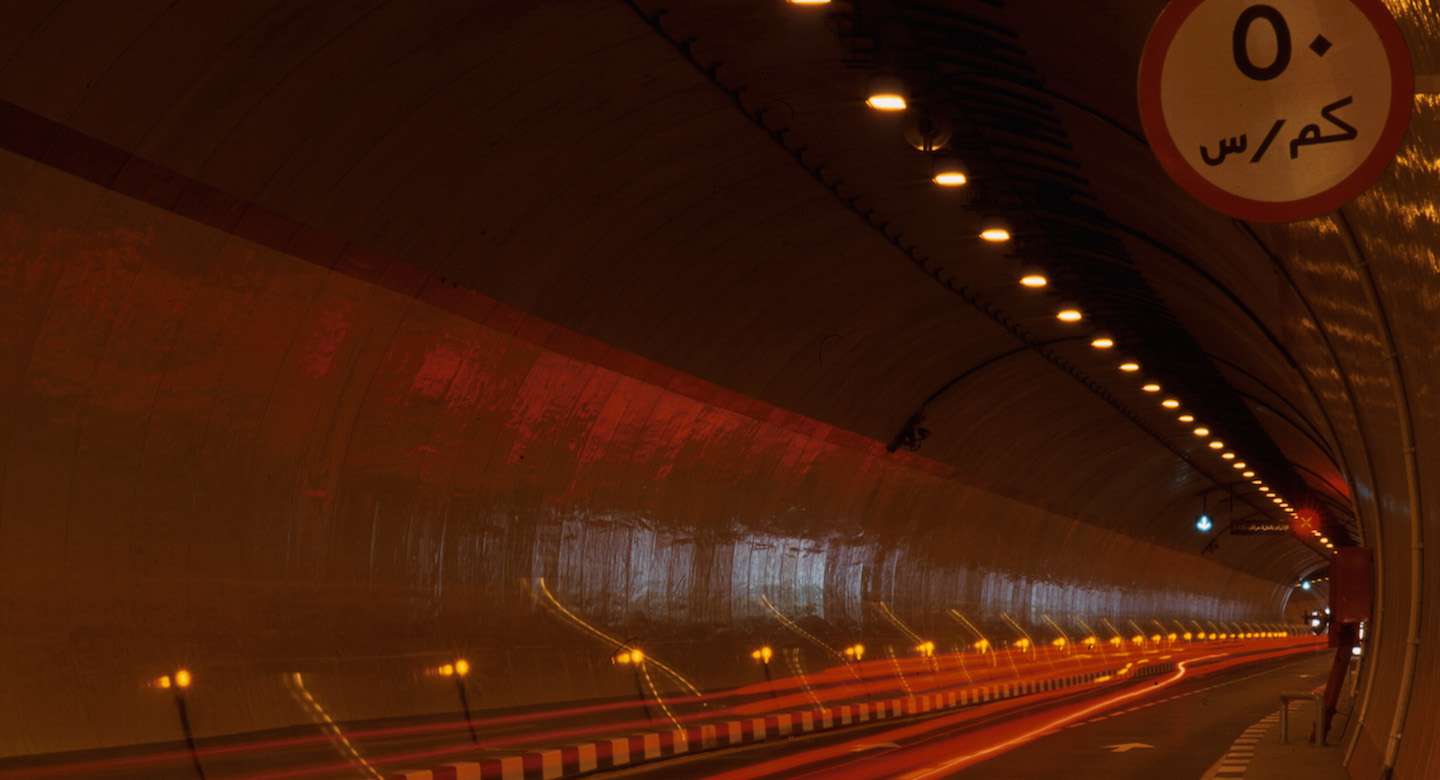

The A86 west tunnel, which connects Rueil-Malmaison and Jouy-en-Josas, south of Versailles, achieves a key objective for the Île-de-France region dating from the 1970s: to complete the A86 ring road around Paris. This is an innovative, 10-kilometre tunnel consisting of two superimposed traffic levels (one in each direction) reserved for light-weight vehicles. It is connected in the north to A86 at Rueil-Malmaison and to the south to RN 286 at Jouy-en-Josas. An intermediate interchange connects the motorway to the A13 at Vaucresson-Le-Chesnay. Thanks to this tunnel, Rueil-Malmaison is a mere 10 minutes from Jouy-en-Josas, instead of the 45 minutes required using other routes. From the choice of colours to lighting, the air-renewal system to road signs, everything has been taken into consideration to provide motorists with a safe and pleasant drive.

El Teniente – the world’s largest underground copper mine – is located at an altitude of 1,500 to 1,900 metres in the Libertador General Bernardo O’Higgins region in the Andes mountain range. The project for which we were commissioned by Codelco includes the blasting of two tunnels, each 9-km long with an average cross-section of 65 m² (one to transport staff and the other to carry ore), as well as the construction of two intermediate access tunnels for a total length of 6 km. These tunnels created a new level in the El Teniente mine to extend its operation for another 50 years.

Following its participation since 1981 in the construction of the first metro line in Africa (in Cairo) and from 1993 to 1997 to a second metro line, VINCI Construction Grands Projets began work in June 1998 on the Al Azhar road tunnels. The project, located in the historic centre of Cairo, the old Fatimid city, and the Khan el Khalily district, provided a considerable technical and scheduling challenge. Work carried out for the National Authority for Tunnels included building two road tunnels, 2.6 and 2.8 kilometres long, respectively, trench junctions with existing roadways, and additional structures. The tunnels, which have a diameter of 8.4 metres, were excavated with a TBM. The worksite was particularly challenging given space restrictions, dense pedestrian and motorised traffic, the proximity of buildings, underground utility networks, and flyovers.

The Maliakos-Kleidi project on which VINCI Construction Grands Projets was mandated consisted in rehabilitating and developing a motorway. This infrastructure is 245 kilometres long: 205 kilometres of motorway were to be rehabilitated and 40 kilometres of new motorway (the focal point of the project) were to be built. The new section to be created as part of a design-build mandate also includes construction of 3 dual motorway tunnels (11 kilometres long in total) to prevent the above-ground crossing of the Tempi Valley, which is a tourism destination, two dual flyovers, and embankments featuring small structures and hydraulic works.

VINCI Construction Grands Projets was mandated by the ministry of transport, public works, and water management in the Netherlands to design and build a 16-kilometre section including a composite bridge (steel structure) spanning the Hollandsch Diep (1,190 metres long), two underwater tunnels crossing the Oude Maas and Dordtsche Kil (2,640 and 2,600 metres long, respectively), a 1,000-metre access viaduct, various engineering structures such as bridges and trenches, including the 935-metre Mokhoek open trench as well as 8.5 kilometres of railway infrastructure slabs resting on 27,000 driven piles.

This mandate is Lot Number 4 of the HSL project (fourth geographical sector out of a total of five for the high-speed line connecting Amsterdam to the border with Belgium).

In January 2006, the Entreprise Métro d’Alger entrusted the construction of Algiers’ first metro line to a consortium consisting of VINCI Construction Grands Projets, Siemens Transportation Systems and the Spanish company CAF. It was a contract for the turnkey delivery of a 9.5 km rapid transit line with a rolling stock of 14 trains for the Algerian capital. Our portion consisted of the finish and layout of 10 stations (nine underground and one overground), as well as the construction of a 16,000 m² service building and maintenance rooms.

VINCI Construction Grands Projets was responsible for the civil engineering works, architectural layout of the stations, electromechanical equipment, escalators as well as the Anassers control station and the Bach Djerah maintenance rooms.

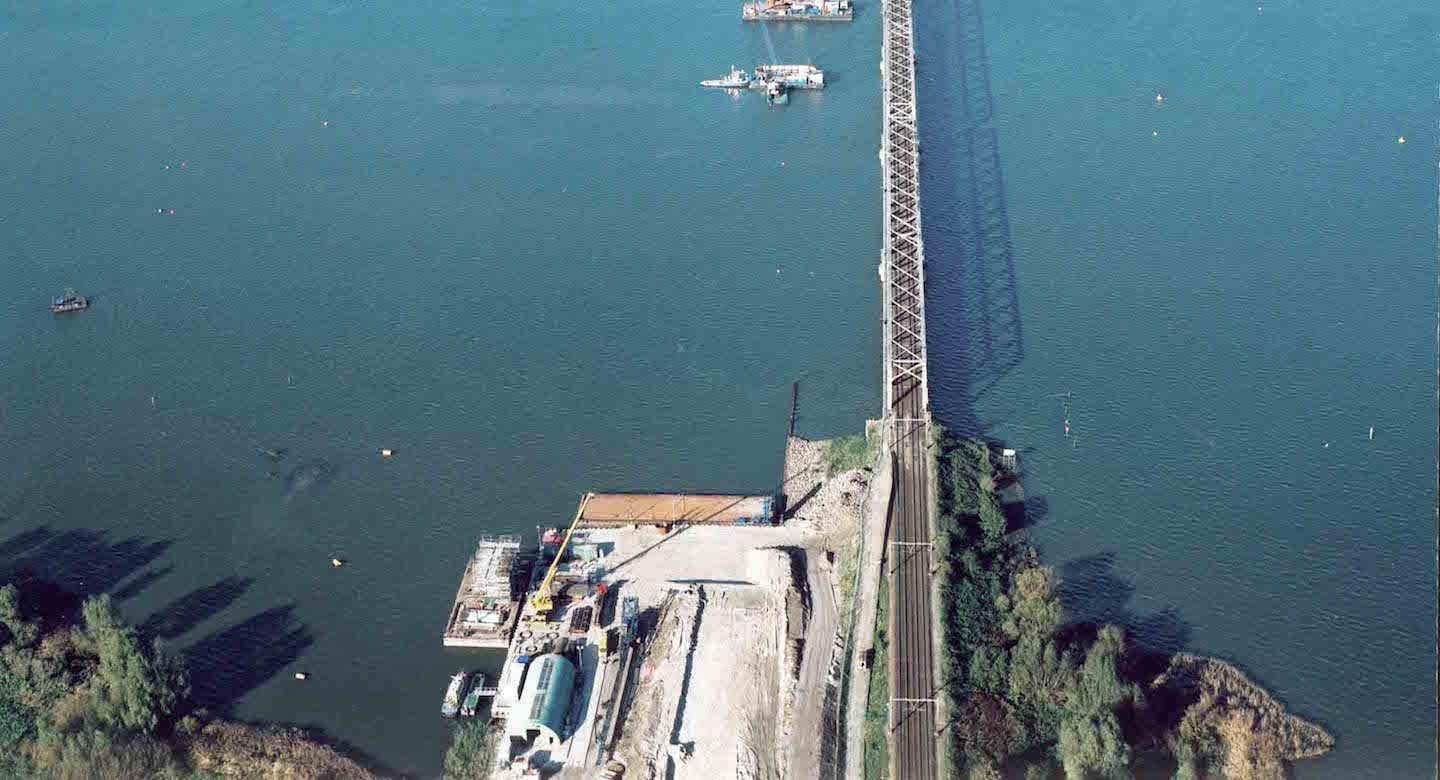

Construction of this dual rail tunnel below the Pannerdensch Canal was part of the “Betuwe” project, a new rail line designed to convey merchandise between the port of Rotterdam and Holland’s border with Germany. This 160-kilometre line can accommodate container railway cars. The work package assigned to us called for the design and construction of the Pannerdensch tunnel, a 6.3-kilometre structure. The project included construction of a dual bored tunnel 1,620 metres long (8.5 metres in inner diameter), portals and access ramps over a distance of 1,200 metres, and 3.3 kilometres of railway platform made from backfill material. In addition, the Pannerdensch Canal tunnel possesses a special feature: it is equipped with gates (square cofferdams) at either end designed to prevent flooding.

The Øresund crossing connects Copenhagen Airport to the city of Lernaken, south of Malmö. It includes, in succession, a tunnel, an artificial island, a viaduct, a cable-stayed bridge, and a second viaduct. The infrastructure, which as a whole extends over a distance of 16 kilometres and accommodates both a highway and a rail line, is the result of 3 major contracts. The first contract called for the construction of a tunnel, the second for dredging operations, and the third for a bridge. VINCI Construction Grands Projets was mandated to design-build the tunnel. To be more specific, this project included construction of an submerged tunnel 3,510 metres long enclosing a dual 2-lane highway and double-track rail line (making it then the longest structure of its kind in the world). The tunnel includes gateways and access ramps at both extremities, technical buildings housing the ventilation systems, and exits linking to road and rail networks.

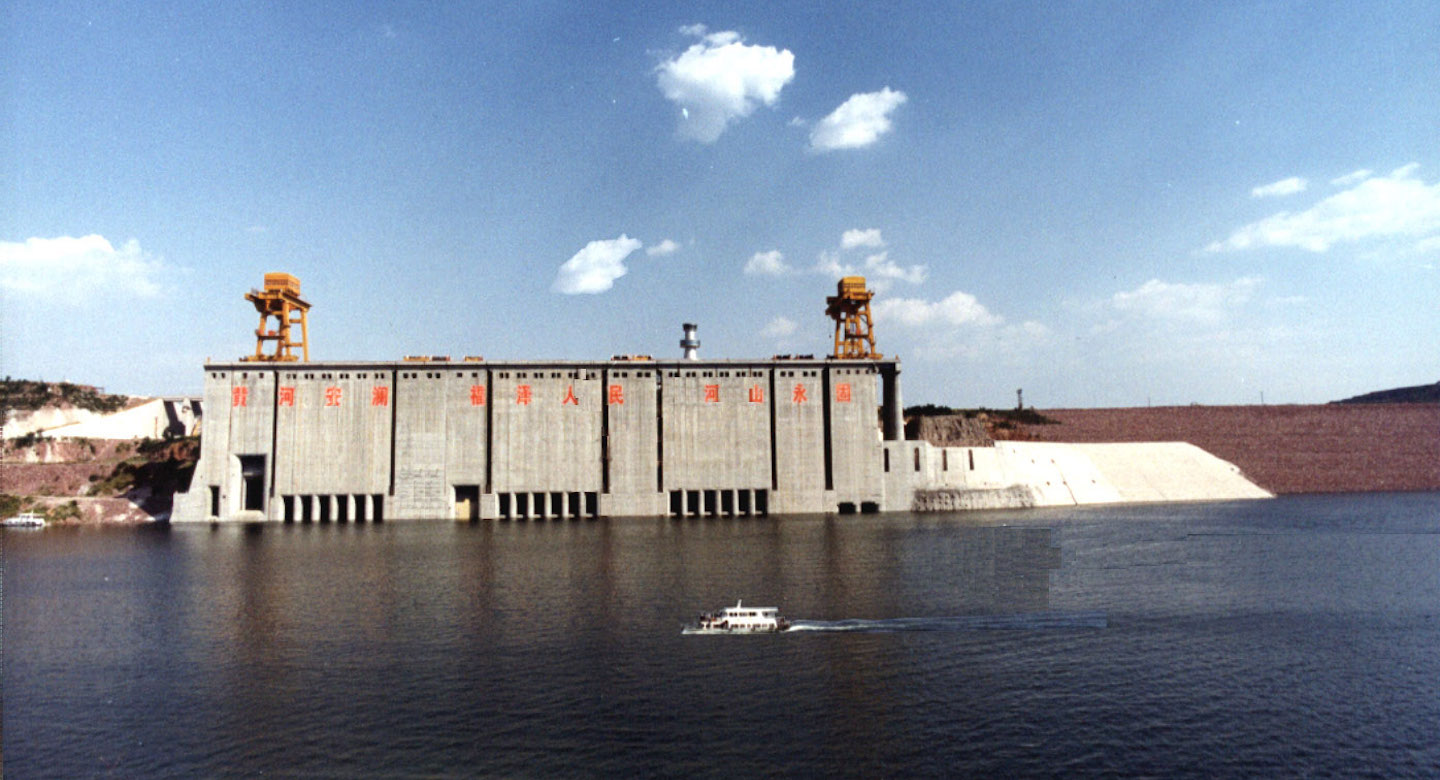

The Xiaolangdi hydroelectric power station on the Yellow River, located 180 kilometres from Zhengzhou, 40 kilometres from Luoyang, and 600 kilometres from Beijing, marks the achievement of a longstanding aspiration, namely, to “tame” the Yellow River, the cradle and scourge of Chinese civilisation.

The structure consists of a sloping earth-core rockfill dam 154 metres high and 1,317 metres long at the crest, a water intake 112 metres high and 278 metres wide, and an underground power plant 252 metres long, 26 metres wide, and 61 metres high. From 1994 to 1999, Dumez-GTM took part in building this power plant as the lead contractor in the joint venture in charge of the project. The primary objective was to control sedimentation in the Yellow River to mitigate its destructive flooding. One of the defining characteristics of this structure, however, is that it meets a multiplicity of objectives, including power-generation and improved use of water for agriculture in the region.

We were commissioned by Eurotunnel to build three key turnkey tunnels with a total length of 150 kilometres. The tunnels, which run for 10 kilometres underground and 54 kilometres beneath the sea, include: 2 single-track rail tunnels and 1 service tunnel. Drilled to a depth of 25 to 45 metres below the seabed of the English Channel in a rocky layer of “blue chalk”, this underground rail link connects France to England.