50 YEARS’ EXPERIENCE AS A CONTRACTOR FOR ENERGY PROJECTS

Our expertise in engineering, civil engineering and process business lines underpins our ability to carry out highly technical design-build projects and ensure all their interfaces. It has enabled us to develop contractor and project-management skills in a complex environment and to establish ourselves as a key player in the sector. Our clients therefore benefit from a centralised and global approach to project management, which optimises the control of risks, costs and deadlines.

LNG (Liquefied Natural Gas): As storage-tank specialists, we also provide solutions for regasification or liquefaction terminals by combining our know-how with that of our partners.

LPG (Liquefied Petroleum Gas): We offer turnkey solutions for bottling terminals, from advice (design, available space, budget) to the design and construction of suitable storage tanks (spheres, bullets, etc.) in our Dunkirk workshops before delivery to the site.

This know-how in heavy boiler works and the ability to produce outsize items benefit the entire energy value chain: fuel storage, renewable marine energy and nuclear energy.

UNIQUE ASSETS AT THE SERVICE OF OUR CUSTOMERS

The ability to deploy anywhere in the world

We stand out for our ability to deploy rapidly for large-scale projects on five continents, and to work in the most complex environments.

Combined with our financial strength, our expertise in the design and construction of energy infrastructure, particularly LNG and LPG storage tanks, has enabled us to carry out major projects in every part of the world.

Global and unified project management for competitive offers

Our extensive engineering resources, as from the process, guarantee our clients have a single interface and benefit from optimised project management. In particular, we offer advanced storage-tank expertise and the ability to make use of all engineering disciplines during the project.

We are able to offer the most competitive solutions thanks to our cutting-edge expertise (in-house production of the primary component, including 9% nickel), a network of specialised partners and subcontractors, and a purchasing and logistics department that enables us to offer alternatives regardless of the environment (e.g. absence of roads and transport by ship and ice-breakers, etc.) at a reduced cost and on time (e.g. the construction of Yamal LNG tanks completed a year ahead of schedule is a case in point).

Four cryogenic LNG tanks in the heart of Western Siberia, beyond the Arctic Circle (Russia)

AN ABILITY TO OPERATE IN EXTREME CONDITIONS

We have earned an unrivalled reputation for designing and building infrastructure in complex environments, whether in deserts (extreme temperatures in Algeria or Wheatstone, Australia), humid tropics (100% humidity on the Bonny Island site, Nigeria) or the Arctic (up to -50 °C and no daylight for several months without any serious accidents on the Yamal project in Siberia, Russia).

This ability is rooted in the development of exceptional know-how, which covers all stages of the project, from basic engineering to execution, while guaranteeing efficient studies (constructability, design, operability, etc.), including in regions with high seismic risks, with recognised business-line expertise (base isolation, treatment to prevent soil liquefaction, etc.).

Similarly, our references allow us to offer designs that comply with all international technical standards.

We adapt our construction methods to the projects’ constraints: modularisation to shorten construction times, concreting in hot weather in desert environments (temperatures above 40 °C) or in an Arctic climate (down to -50 °C), and use of slip or self-climbing forms for projects undertaken with limited manpower in hurricane-prone regions illustrate and testify to our know-how that we draw on for our projects and clients.

The integration of environmental and safety issues with our approaches, Environment in Design, which ensures that the environmental impact of our structures is taken into account from the design phase, and Safety in Design (shared within VINCI Construction), which enshrines our ambition to ensure optimum safety during the construction, operation and maintenance of infrastructure, also guarantees optimum risk management.

Our commissioning teams also play an active role within the engineering department up to on-site deployment to ensure the start-up of the installations.

Wheatstone LNG storage tanks (Australia)

OUR VALUES AND COMMITMENTS

- Safety is our top priority. We make every effort to reduce the number of serious accidents to zero.

- We comply with the most stringent quality, environment and sustainable-development standards in the industry to satisfy our clients and partners, and to meet our own commitments, especially with the aim to reduce our carbon footprint, studying solutions to reduce our environmental impact, multi-cultural teams, etc.

- Meeting of deadlines: we deliver critical equipment on time for large, high-potential projects while applying a risk-based management approach.

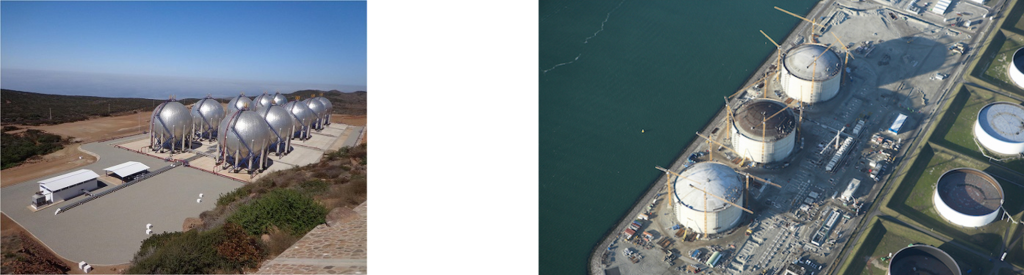

Zeta storage spheres (Mexico) Project Gate LNG in Rotterdam (Netherlands)

To know more about our LNG & LPG expertise, please download our LNG & LPG Terminals brochure

To know more about our LNG & LPG expertise, please download our LNG & LPG Terminals brochure

To know more about the VINCI group Oil & Gas offer, please download our brochure Oil & Gas: from upstream to downstream

To know more about the VINCI group Oil & Gas offer, please download our brochure Oil & Gas: from upstream to downstream