TECHNICAL OVERVIEW

The construction work required many precautions to be taken to preserve the surrounding buildings. The worksite covered the perimeter of Cour Napoléon and went three levels beneath the great pyramid to the very foundations of the Louvre.

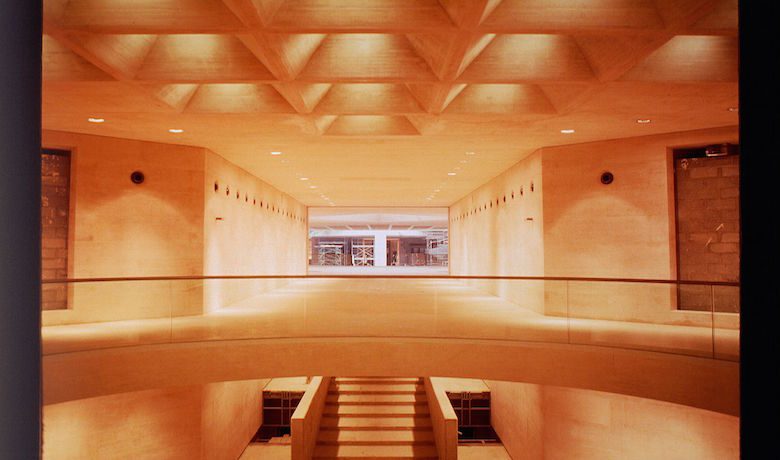

Careful attention was paid to the quality of materials used and the layout of the Grand Louvre structure. White architectonic concrete, exactly matching the tone and colour of the white Burgundy stone floors and walls, was used to cover the grey concrete employed in the construction phase. Likewise, special care was devoted to the pyramidal frames of the ceiling formwork to ensure that no trace of the construction was visible. In addition, the concrete was cast in segments of 500 m3 to prevent construction joints from becoming visible.

In addition to quality-related requirements, the project included bold technical features. For the reception hall below the great pyramid, for instance, a composite steel and concrete structure was used for the construction of five large metal structures covered in white concrete bearing the weight of the pyramid. But as the pyramid is very rigid and the elongated beams are deformable, to ensure the overall solidity of the structure, resistance and deformation studies were carried out.