The public-private agreement is for a 2,500 feet-long (762 metres) cable-stayed bridge across the Ohio River that will link Louisville, Kentucky to Southern Indiana, a 1,680 feet in length (512 metres) twin-bore tunnel on the Kentucky approach to the bridge, and 19 additional bridges, along with associated roadway improvements and other related infrastructure work. The new East End Bridge will be located about 8 miles (13 km) from downtown Louisville, connecting the Gene Snyder Freeway to the Lee Hamilton Highway.

The works, scheduled to take 3.5 years, will be executed by a design-build joint venture including Walsh Construction (60%), VINCI Construction Grands Projets (40%) and Jacobs Engineering for the engineering works. Construction is set to commence in the summer of 2013 and completion is expected by autumn 2016.

The total value of the contract is around $1 billion (approximately €787 million).

The consortium, led by VINCI Concessions, will be responsible for the operation, routine maintenance and rehabilitation of the infrastructure for a period of 35 years. It will be paid through license-fees calculated on the basis of the infrastructure’s availability.

The East End Crossing is part of the broader Ohio River Bridges Project, one of the largest transport improvements in the United States. It will address traffic congestion issues and improve transport safety.

The contract is worth $366 million.

The bridge will be located 3 km north of the Gatun locks, near the city of Colon. The contract covers construction of a 1,050m-long cable-stayed concrete bridge carrying two lines of traffic in each direction, with a central span of 530 metres and pylons with a height of 212.5m. It will have a vertical clearance of 75m above the canal. The Atlantic Bridge will be the longest concrete cable stayed bridge in the world with a central span of 530 metres.

It will notably allow passage of the largest container ships (Post-Panamax), in accordance with the canal expansion programme. It will also allow vehicles to cross the Panama Canal on the Atlantic side, whether or not the locks are in operation.

To avoid disrupting navigation in the canal, it will not be possible for the work to be carried out in the waterway itself, which means the deck will have to be cast in place. The contract also includes construction of access viaducts on either side of the bridge with a total length of 2 km, together with connections to the existing road network.

Work is expected to start in January 2013 and last 3 ½ years.

This contract, which marks the historic return of a French company to the Panama Canal, is yet another addition to VINCI Construction Grands Projets’ prestigious portfolio of bridges: Pont de Normandy (France), Severn Bridge (United Kingdom), Confederation Bridge (Canada), the bridge over the Tagus (Portugal), and Rion-Antirion (Greece).

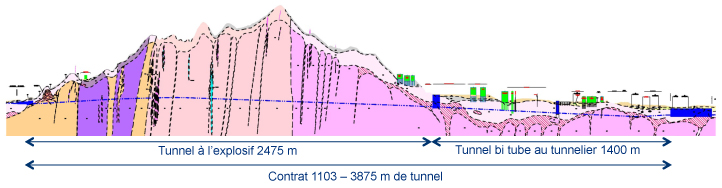

The contract comprises the construction of 2,475 metres of drill and blast tunnel and 1,400 metres twin tunnels to be excavated by means of a slurry TBM with 7.4 metres diameter.

The works commence 22 October 2012, with a contract duration of 68 months.

The new Shatin to Central Link is split into 10 main contracts and provides for the realization of a 12 kilometres underground mass transit line, the construction of 4 new stations and the reconfiguration of 2 interconnecting stations.

VINCI Construction Grands Projets has already participated in the construction of the Hong Kong Mass Transit railway between 1998 and 2002, with the completion of 5 tunnels under the Black Hill Mountains for the extension to the town of Tseung Kwan O.

The project is part of a contractual agreement between China Henan Company and ARA-Sul (the regional water management authority), funded by the African Development Bank, for the construction of an auxiliary spillway.

The Massingir Dam is located on the Olifants River, a tributary of the Limpopo, in southern Mozambique. The dam was built in the 1970s to irrigate the land, control floods, and generate electrical power, but its spillway was unable to discharge peak floods. The auxiliary spillway, equipped with 14 straight fusegates, each 5.8 high and 11.23 m wide, will, in conjunction with the main spillway, provide total discharge capacity of 34,000 m3/s. The fusegate system, developed exclusively by Hydroplus, was selected by the firm Tractebel Engineering, a subsidiary of GDF SUEZ, from among other solutions, including fixed labyrinth spillways and fuseplug dykes.

Design studies will be conducted in 2012 and installation will be carried out in 2013.

This first ever contract in Mozambique marks Hydroplus’s return to southern Africa, where several other dams are equipped with fusegates: Eikenhof and Shongweni in South Africa, Ruti and Ruia in Zimbabwe, and Kamuzu in Malawi.

The project, which is part of the renovations to be done to the railway line running between Malmö and Göteborg, aims to considerably increase traffic on the line and to double the maximum weight of freight trains using this route.

The Åsa tunnel boring machine was designed to drill into very heterogeneous terrain (highly altered or instable firm rock) in which water seepage can reach high levels (up to 400 l/s). An entire range of terrain treatment processes (in particular, injection), allowing to overcome these difficulties while being in compliance with the water laws applicable to this project, can be carried out at the tunnel boring machine level.

In order to help the tunnel boring machine make its way through the northern segment of the second tunnel that is yet to be dug, injection work is currently being carried out from two branches. The purpose of this injection work is to reduce water seepage into the 800-metre-long highly aquiferous area known as Lya.

At the same time, the freezing of the Mölleback fault, made up of altered, fractured and heterogeneous rock, started on the first 85 metres. Digging a gallery in the frozen ground is ongoing in order to allow the freezing of the next 115 metres. The Åsa tunnel boring machine is scheduled to start excavating in the Mölleback fault in early summer, 2013.

85 % of the two main tunnels have been completed. The remaining 3 kilometres of tunnel to be dug should be completed by the end of 2013, and the project is set for commissioning in 2015.

In 2002, VINCI Construction Grands Projets, along with Skanska, was mandated to design and build these two tunnels, each 5,500 metres long, with an inside diameter of 9.04 metres, through the Hallandsås hillside, as well as twelve inner tube tunnels (four measuring 39 metres long, and eight measuring 21 metres long). The first two tunnels were bored on August 25, 2010.

This phase marks the beginning of the 7-kilometre tunnel excavation operation, which will be completed in two years by this Herrenknecht TBM that is 120 metres in length and 8.85 metres in diameter.

The Lee Tunnel project received the “Infrastructure Award” as well as the “Greatest Contribution to London Award” for the excellent quality of its diaphragm walls; the prizes were awarded at the ICE (Institution of Civil Engineers) ceremony held in London on March 5, 2012.

The project calls for the construction of a 7-kilometre tunnel for storm and wastewater in East London that will reduce by half the 32 million cubic metres of wastewater discharged annually in the River Thames by collecting it at the source. The projects also calls for the construction of 4 large shafts as well as supply and installation of the equipment and automation systems needed to manage the effluent and raise it more than 80 metres.

Currently, nearly 430 employees are at work on the project, including about 30 expatriate personnel and VIE (business volunteer program) interns from VINCI Construction Grands Projets and about 20 employees from Bachy Soletanche.

Once completed, Line 3 will cross the Egyptian capital from east to west, from the airport to the districts west of the Nile. The development of the Cairo metro system is part of a large-scale plan aimed at serving the transport needs of the Greater Cairo area up to 2022. It will help to reduce pollution in Africa’s largest metropolitan area.

3,500 people, including 85 expatriate staff, worked on this project, which took 51 months to complete. The project was built by a consortium, led by VINCI Construction Grands Projets, comprising Bouygues Travaux Publics, Orascom and Arab Contractors. The €235 million Phase 1 civil engineering contract covered construction of a 4.2 km tunnel section and five stations. Meanwhile, VINCI subsidiary ETF-Eurovia Travaux Ferroviaires led the consortium responsible for the track works package. This included the supply and laying of 11 km of track and the power rail in the tunnel.

VINCI Construction Grands Projets built the first two metro lines in Cairo, which now serve nearly four million passengers per day, and is currently working in a consortium with Bouygues Travaux Publics, Orascom and Arab Contractors on Phase 2 of Line 3 (6.5 km tunnel and five stations); Phase 2 is currently 60% completed and is scheduled for handover in early 2014. The National Authority for Tunnels (NAT) is working on the design studies for Phase 3.

VINCI Construction Grands Projets have a long track record in major projects in Egypt and recently signed the design-build construction contract for the new Assiout dam on 12 December 2011.

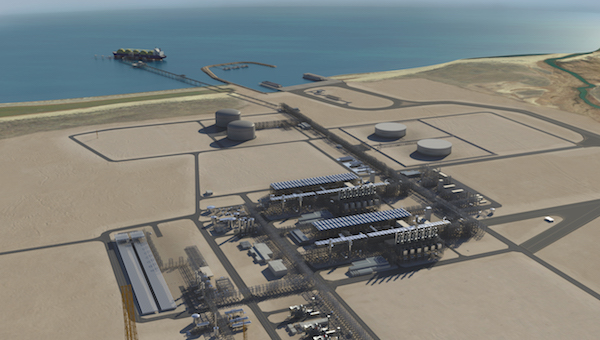

ENTREPOSE Projets, a subsidiary of ENTREPOSE Contracting, and VINCI Construction Grands Projets, both subsidiaries of VINCI, have just signed, in a joint venture with Thiess Pty Ltd, a subsidiary of Leighton Holdings Limited, an engineering, procurement and construction contract for approximately AUD 500 million (about €400 million) covering two full containment liquefied natural gas (LNG) storage tanks with a capacity of 150,000 cubic metres each as well as two condensate storage tanks with a capacity of 120,000 cubic metres each.

The contract is forecast to create about 475 jobs in Western Australia’s Pilbara region, and 75 per cent of the content will be Australian, including 55 per cent West Australian. There will also be significant Indigenous involvement.

The Chevron-operated Wheatstone Project, a LNG and domestic gas project managed by Bechtel Australia, is located near Onslow in the North Western Australian region and represents one of Australia’s largest resource projects. The project will commence immediately with construction to last from 2013 to 2016.

ENTREPOSE Projets and VINCI Construction Grands Projets have built more than 30 LNG storage tanks in 10 different countries over the last 20 years, including three 180,000 cubic metres capacity tanks at the Gate regasification terminal in the Netherlands in 2011.

The works, valued at 266 million euros, will be carried out by a consortium composed, in equal parts, of VINCI Construction Grands Projets (leader), Arab Contractors and Orascom. The works will start on 2 May 2012 and should take a little over 5 years to complete (64 months).

Located on the Nile, some 250 kilometres to the north of Luxor, the new Assiut dam will replace an existing dam, built early last century 400 metres further upstream.

This project aims to regulate the flow of the Nile, for irrigation purposes and for the production of electricity (32 MW, produced by four 8 MW turbines). It will have 2 locks, to allow through river navigation.

The project is being financed by KfW and the Egyptian government.

This new contract will add to the Group’s numerous references for Egypt, where it has been present for over a century. After delivering the Aïn Sukhna rolling mill and the Naga Hammadi dam in 2008, VINCI Construction Grands Projets is currently working on phases 1 and 2 of Line 3 of the Cairo Metro, having already led the construction of Lines 1 and 2. The diversity of the projects carried out in Egypt clearly demonstrates the wide range of expertise of VINCI Construction Grands Projets, and testifies to a long term relationship with the Egyptian authorities.

VINCI Construction Grands Projets was responsible for the civil engineering, the architectural fitting-out of the stations, the electromechanical equipment, the escalators, the ventilation and the smoke extraction system for the tunnel and the stations, as well as the control centre and the maintenance workshops.

Siemens France supplied the signalling, Trainguard MT CBTC train automation technology, the telecommunications, the track, the complete electrification of the line, the ticketing technology and the Central Control Room. As the consortium leader, Siemens also oversaw project management and all systems engineering functions.

CAF supplied the rolling stock (14 six-carriage trains), and the auxiliary vehicles used for maintenance work.

The first segment of Line 1 of the Algiers subway system includes 10 stations (from Tafourah Grande Poste to Haï el Badr) covering a 9-kilometre stretch. The first metro line is the cornerstone of the Algerian capital’s future structuring network.

EMA (Entreprise du Métro d’Alger) has entrusted operation of the first subway line in Algiers to RATP El Djazaïr, a subsidiary of the RATP group.