TECHNICAL OVERVIEW

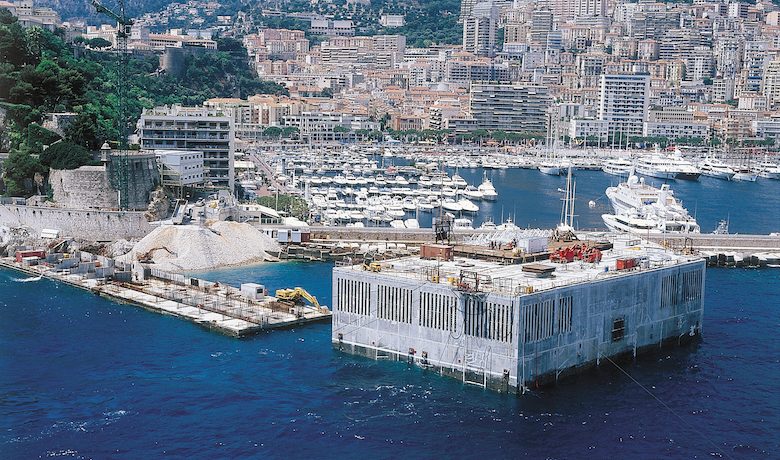

The Condamine Port extension involved three parts. This infrastructure consists of a one-hectare platform at the foot of Fort Antoine. This platform was built from backfill and then fitted with six caissons. These concrete caissons, with a height of 10, 20 and 30 metres and weighing between 15,000 and 35,000 tonnes, were built using steel-reinforced panels and formwork. This was followed by the construction of a semi-floating 30 metre-wide and 352 metre-long breakwater attached to the embankment through a metal ball joint.

In addition to its primary function of protecting the waters of the outer port and port itself, it was intended to provide docking facilities for cruise ships on both the port and sea sides. It is connected to the platform through the abutment caisson to which it is attached by a large metal wheel. The sea side end is fastened by two sets of anchors fixed at a depth of more than 55 metres. The breakwater has at its base two 8 metre-wide wings for stabilisation to support a total underwater 44 metre-long mooring. Their role is to counter rolling and pitching. The structure is 3 metres above water level on the port side and 6.6 metres above on the sea side. The large submerged volume allowed for the installation of 360 parking spots on four levels and a dry harbour for 25,000 m² of storage on two levels. The outer harbour is protected through the “fixed seawall” technique, for which a patent application was filed by the Principality of Monaco. The “fixed seawall” principle consists of mobilising the inertia of the mass of water between the interior of a caisson and the bottom of the sea, which behaves like a wall to bounce back swelling waves. Finally, the structure has a 145-metre counter-jetty supporting its ends. The land side is on an abutment and the sea side is on a supporting caisson. This shelters the outer port better and creates an additional basin for large pleasure boats. It is a fixed structure with a prestressed concrete caisson 2 metres above water level.