BACKGROUND

Heathrow is a leading international airport. Prior to the expansion project, it had an annual capacity of 50 million passengers. In 1998, it served nearly 60 million. That is why an expansion project to increase capacity was launched. The new terminal – Terminal 5 – was designed to receive 30 million passengers a year.

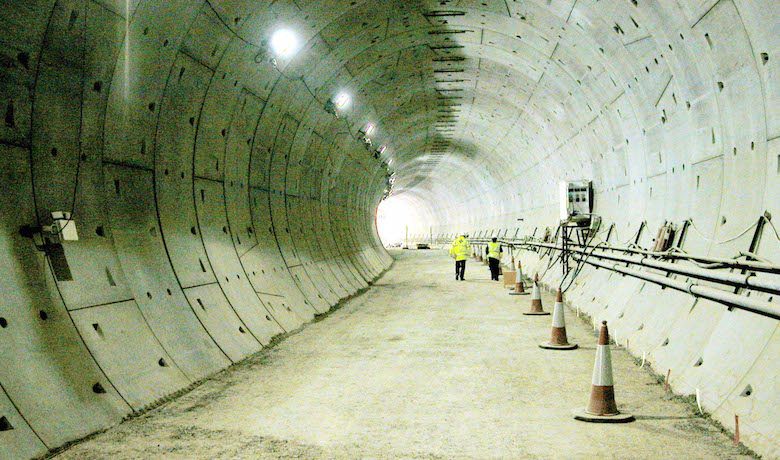

So, to connect the airport and the new terminal, we were mandated to create 2 “Tube” tunnels, 2 rail tunnels, 2 road tunnels reserved for internal airport traffic connecting the airport, new terminal, and existing terminals, and a tunnel to evacuate stormwater. All of these tunnels were excavated in London’s clay soil, which provides stability (which is why London was the first city to build an underground public transport network.