The Link Alliance, including VINCI Construction Grands Projets (lead company) and Soletanche Bachy International, subsidiaries of VINCI Construction, and their partner Downer, plus designers Aecom, WSP-Opus and Tonkin & Taylor – signed on 20 October 2020 the contract for lots 5 and 7 for the City Rail Link programme in Auckland, New Zealand.

Lot C5 includes the construction of two structures (grade-separated junctions) and 2 km of new track, to be constructed while maintaining traffic on the North Auckland Line.

Lot C7 includes installation of power supply, overhead lines, signalling and the control system for the entire City Rail Link.

These contracts follow on from the contract for lot 3 won in July 2019 by the same consortium, covering design/construction of a 3.45 km railway line extension, including 3.2 km of tunnel and three new stations.

The contracts are of the “Alliance” type, which combines the designer-builder consortium and the client – City Rail Link Limited – into a single team to undertake the project. Delivery of all three lots (3, 5 and 7) is scheduled for 2024.

At a total cost of 4.419 billion New Zealand dollars (2.586 billion euros), the City Rail Link project will double the number of people able to reach Auckland’s city centre within 30 minutes. This new train line is designed to accommodate 54,000 passengers per hour during peak hours, or the equivalent capacity of two motorways with four lanes in each direction.

This project illustrates VINCI Construction’s ability to support large urban centres in successfully delivering their urban mobility projects, as it is doing in France, Hong Kong, Singapore, Qatar, USA and Canada.

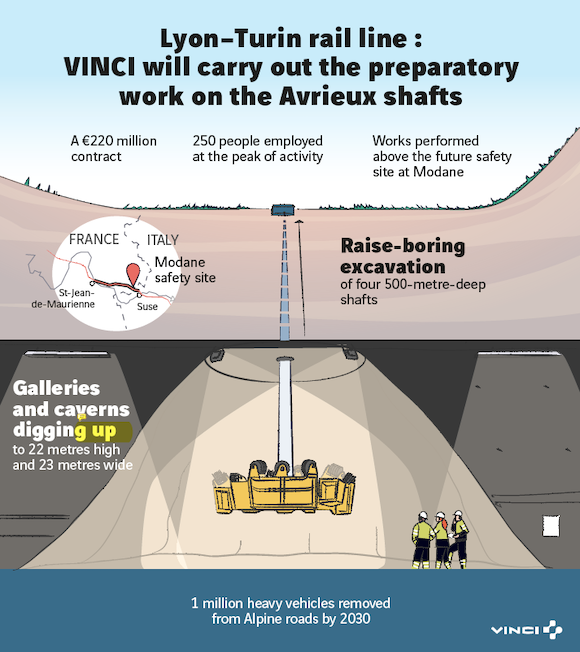

The owner, TELT (Tunnel Euralpin Lyon Turin), has awarded works package 5A of the Lyon–Turin rail line to a consortium* led by VINCI Construction Grands Projets. The works package involves preparatory work perpendicular to the future safety site at Modane, near the midpoint of the 57.5-kilometre base tunnel that will connect the international stations in Saint Jean de Maurienne (France) and Susa (Italy).

The €220 million contract for works package 5A involves construction of the four 500-metre-deep Avrieux shafts using raise-boring machines (mechanical excavators operating from the base of the future shafts). This technique optimises work safety, costs and time. The work also involves digging galleries and seven caverns, using conventional methods (explosives), at the foot of the existing Villarodin Bourget–Modane decline, which is up to 22 metres high and 23 metres wide.

The project will employ up to 250 people over the coming 36 months.

The Lyon–Turin line is part of a programme designed to upgrade passenger travel and expand trade in Europe. It is setting in motion a transition that will make transport more sustainable by shifting long-distance freight from roads to rail lines. By 2030, the Lyon–Turin rail line will replace 1 million heavy vehicles on Alpine roads and lower greenhouse gas emissions by about 3 million tonnes of CO2 equivalent per year.

VINCI Construction is applying its expertise in underground works in several countries, notably on public transport projects aimed at fostering sustainable development in host cities and regions. VINCI Construction subsidiaries are working on several rail transport systems in the United Kingdom (HS2), Ottawa (new LRT system), France (several Grand Paris Express projects), Doha (two metro and LRT lines), New Zealand (Auckland’s City Rail Link), Hong Kong and Singapore (Thomson Line).

*The consortium encompasses VINCI Construction subsidiaries VINCI Construction Grands Projets (lead), Dodin Campenon Bernard and VINCI Construction France (65%), alongside Webuild (33%) and Bergteamet (2%).

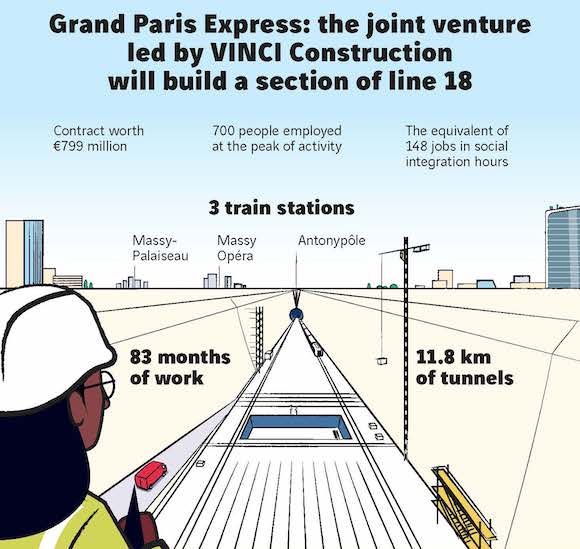

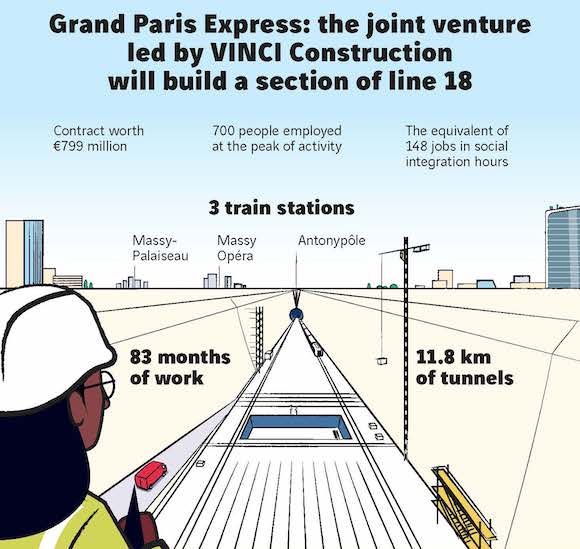

Société du Grand Paris has awarded the construction contract for works package 1 of Line 18 of Grand Paris Express, the biggest urban mobility programme currently under way in Europe, to the joint venture* led by VINCI Construction Grands Projets. This first section will link Orly airport to Massy-Palaiseau; Line 18 will then be extended to Versailles.

Worth €799 million, of which 20% reserved for SMEs, the contract calls for digging 11.8 km of tunnels using two tunnel boring machines (TBMs) and building three stations (Antonypôle, Massy Opéra and Massy-Palaiseau), 13 ancillary engineering structures 10 branches connecting with the tunnel, and 850 metres of cut and cover. In total, more than 1 million cubic metres of material will be excavated.

At its peak, the contract will employ up to 700 people (500 labourers and 200 supervisory staff). Over the 83-month duration of the worksite, it will also create the equivalent of 148 full-time jobs for people in social integration programmes.

In addition, the VINCI Group has established an endowment fund, Chantiers et Territoires Solidaires, to support non-profit entity initiatives relating to employment and the social fabric of communities located close to Grand Paris Express projects.

As part of the Grand Paris Express programme, the consortium is currently executing, on Line 15 South, the works packages between Fort d’Issy-Vanves-Clamart and Villejuif Louis Aragon, as well as the Noisy-Champs station works package, and is responsible for extending Line 14 South towards Orly. The VINCI Group is also working on other Grand Paris Express works packages through specialist activity subsidiaries of VINCI Construction, Eurovia (for laying rail track) and VINCI Energies.

*The joint venture comprises VINCI Construction Grands Projets, leader, VINCI Construction France, Dodin Campenon Bernard and Botte Fondations, all subsidiaries of VINCI Construction and representing 75% of the joint venture, together with Spie batignolles génie civil and Spie batignolles fondations, both subsidiaries of Spie batignolles and representing 25% of the joint venture.

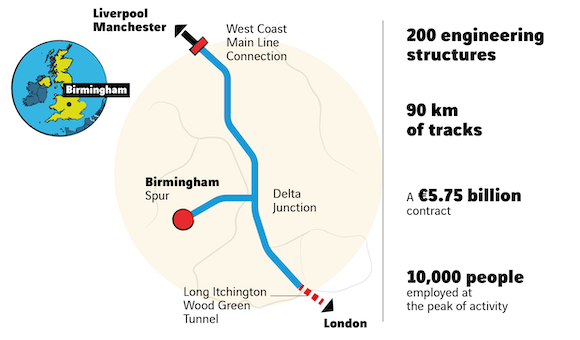

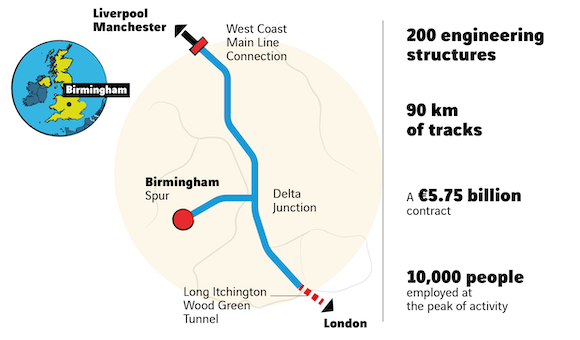

The 50:50 joint venture between Balfour Beatty and VINCI* has been awarded the HS2 lots N1 and N2 phase 2 contract (construction) on 1 April 2020. Lot N1 and Lot N2 are between the Long Itchington Wood Green tunnel to the Delta Junction / Birmingham Spur and from the Delta Junction to the West Coast Main Line tie-in respectively.

Phase 1 for these contracts had been awarded in July 2017 for the design of the West Midlands area. More than 500 engineers and technicians, including the joint venture’s designers, worked successfully to reach this milestone today and enable the project to switch from design to construction.

Spanning on approximately 90km, the delivery of Lot N1 and Lot N2 will include an impressive number of engineering structures, tunnels and earthworks: 51 viaducts and boxes totalling over 14km and 76 overbridges, 7.5km of twin tunnel, 35 cuttings reaching over 30km, 76 culverts and other underbridges, 66 embankments reaching over 33km, 4 motorway crossings requiring box structures, and 6 interfaces with existing rail requiring both dive-under and overbridge structures. Lots N1 and N2 comprise a total of 1.8 million cubic meters of concrete and 32 million cubic meters of cut and landfill.

Work will start on site in summer 2020 with all the sanitary and safety rules that prevail according to the Covid-19 pandemic and would last 74 months. At the peak of activity, the project will employ 10,000 people.

The contract awards reflect the innovative and collaborative nature of this long-established and successful joint venture. Balfour Beatty’s in-depth knowledge and expertise of British transport is complemented with VINCI’s major project expertise, including the recently completed SEA Tours-Bordeaux high-speed line in France and rail infrastructure projects in the UK.

Balfour Beatty – VINCI teamed up with Systra and Mott MacDonald and was awarded in September 2019 by HS2 the contract for the construction management of Old Oak Common station in London.

*VINCI is represented by its subsidiaries: VINCI Construction Grands Projets, VINCI Construction UK and VINCI Construction Terrassement.

The health crisis that the world is facing today is exceptionally extensive.

In all the countries where we operate, VINCI Construction Grands Projets is playing its part in efforts to contain the Covid-19 pandemic.

Protecting everyone’s health and safety are our absolute priorities. VINCI Construction Grands Projets is therefore strictly applying public authorities’ recommendations.

In countries that have enforced lockdowns, we immediately took measures so that employees who can work from home are able to do so.

We will systematically help our customers and public authorities complete projects considered non-deferrable, in all cases strictly complying with measures to keep our employees and subcontractors safe.

We are mobilised, worldwide, to contribute to efforts to eradicate this pandemic and to work alongside authorities to prepare to move past this health and economic crisis as rapidly as possible.

Together, we will overcome this ordeal. All together, with our employees, customers, partners and subcontractors, we will show that we are able to rebound.

Let’s continue to build on trust.

On 15 November of this year, the joint venture formed by two VINCI Construction subsidiaries, Entrepose Contracting and VINCI Construction Grands Projets, signed an EPC* contract with Novatek subsidiary OOO OBSKY LNG to build two new cryogenic LNG tanks on the Yamal Peninsula.

“We are extremely proud and honoured that Novatek has entrusted this new project to us following the exemplary on-time, on-budget handover of the first four LNG tanks built in Sabetta for Yamal LNG. The new project is recognition of our expertise in the sector, and particularly of our ability to rise to the challenges of innovative projects to be carried out in extreme environments,” says Entreprose Contracting Managing Director Gaël Cailleaux.

“Two years after the handover of the four Yamal tanks, the challenge of designing and building tanks in this area of the world – where temperatures are below freezing eight months out of the year and can reach -50°C in winter – remains unchanged. We are fully mobilised, with the technical and innovation capabilities of our in-house design and engineering offices, to carry out this contract alongside our partners,” says Fadi Selwan, operations Director, Americas and LNG at VINCI Construction Grands Projets.

In July 2019, VINCI Construction won a contract to build an LNG tank in northern British Columbia, Canada. Having built 14 LNG tanks around the world over the past decade, VINCI Construction is widely respected for its ability to meet the expectations of the oil and gas majors in every type of environment.

*Engineering, Procurement and Construction

On 14 November 2019, VINCI Construction Grands Projets signed a contract with the Phnom Penh Water Supply Authority to design and build the Bakheng water treatment plant in the northern outskirts of the Cambodian capital.

The first phase of the project, with a value of $155 million (€141 million), covers construction of:

- a first treatment line with a capacity of 195,000 cu. metres per day,

- the intake in the Mekong River with a capacity of 390,000 cu. metres per day,

- two 1.4 metre diameter pipelines with a length of 1.5 km to carry water from the Mekong to the treatment plant,

- a 2 metre diameter pipeline with a length of 7.8 km (including a 630 metre river crossing to be built using a microtunneling machine) to bring drinking water to more than 500,000 inhabitants of the capital city.

To minimise the plant’s carbon footprint, its electricity requirements will be partly supplied by 27,000 sq. metres of solar panels with 3.8 MW installed capacity.

The project, co-financed by the French Development Agency, the European Investment Bank and the Phnom Penh Water Supply Authority, will employ more than 500 local workers and supervisory personnel at the height of activity.

The contract provides for a second conditional works phase with a value of $45 million (€41 million). This phase is designed to double the plant’s treatment capacity to 390,000 cu. metres per day. Following handover of the second phase, the project will provide drinking water for a population of one million.

The new project confirms VINCI Construction Grands Projets’ commitment to expanding drinking water access in Cambodia. In 2017, the company handed over the Niroth drinking water plant on the outskirts of Phnom Penh and the wastewater treatment plants at the Phnom Penh and Siem Reap airports. This year, the VINCI Construction Grands Projets hydraulic engineering teams also delivered two drinking water plants in Siem Reap and Chamkar Mon (in the centre of the Cambodian capital).

Since it was founded in 2000, VINCI Construction Grands Projets has built water projects that supply six million people with drinking water and treat wastewater for a population equivalent of 2.5 million around the world.

ITER Organization, the international organisation set up in November 2006 to operate and subsequently dismantle the ITER facility; Fusion For Energy (F4E), the European Union organisation responsible for the European contribution to the ITER programme; and Groupe VINCI, leader of the consortium1 in charge of constructing the main buildings at the site, today announced the completion of civil engineering works on the ITER Tokamak2 Building at the Saint Paul lez Durance/Cadarache site in south-eastern France. This major project milestone was symbolically reached with the final concrete pour, on 7 November 2019, of the upper part of the building in which the ITER Tokamak will soon be assembled.

With the on-time completion of the Tokamak Building civil engineering works, the metal frame of the roof can be installed and the ambitious First Plasma3 target in 2025 maintained.

The civil engineering project, which got under way in 2010, called for exceptional complex project management capabilities and cutting-edge expertise.

The teams working within the VINCI-led consortium set up an efficient and agile project organisation enabling them to integrate all design changes requested by the ITER scientific teams as construction proceeded. The mobilisation of the VINCI design and works teams, the use of cutting-edge digital design tools and the complex project management expertise of the VINCI teams made this successful system possible.

The construction of the 73 metre high, 120 metre wide Tokamak Building also required production of highly specific concretes. The worksite teams developed about 10 formulations, some of which have unique features enabling them to shield workers and the environment from fusion-generated radiation. Some parts of the Tokamak Building also called for steel reinforcement density rarely used on projects on this scale (up to 10 times the density of an apartment building wall). Lastly, access to the heart of the Tokamak Building required customised production of 46 heavy nuclear doors. Each 70-tonne door is manufactured in Germany, brought to the site, filled with concrete and assembled in the heart of the Tokamak Building.

“In deciding to take part in the leading construction of the particularly complex ITER buildings, VINCI undertook to help write a new chapter in one of the most ambitious and promising research programmes ever undertaken – a programme designed to reproduce on Earth the reactions that have been taking place in the heart of the Sun and stars for billions of years. Its goal is to harness hydrogen fusion and thereby pave the way for a new era for all humanity by making available a massive source of energy that can be varied at will, is intrinsically safe and has no impact on the climate and the environment. This was a huge challenge to which the men and women at VINCI have been tenaciously and resourcefully rising for nearly a decade. We want to warmly thank Vinci for having been a highly capable, reliable partner sharing our objectives, our standards and our determination. The success of ITER will be theirs.” said Bernard Bigot, Director-General of ITER Organization.

“We are pleased to announce the completion, following a lengthy and complex process, of the civil engineering works for the main building that will house the ITER Tokamak, the world’s largest fusion machine. Europe is the party responsible for building the infrastructure of this extremely ambitious programme. Our close collaboration with VINCI, its partners and more than 700 workers has enabled us to successfully finalise this stage of the project in compliance with the safety, security and quality requirements.” said Laurent Schmieder (F4E), who oversees the team in charge of building construction and electrical systems for the ITER project.

“VINCI Construction and its partners Razel-Bec and Ferrovial are extremely proud of having carried out the ITER civil engineering works. ITER is a one-of-a-kind research programme in terms of its complexity, precision and size. It is an extraordinary human undertaking, but also a huge technical challenge, and we were constantly called on to innovate and expand our expertise. With ITER, we are humbly helping to implement one of the greatest and most ambitious energy projects of our time, designed to make electricity available throughout the world without CO2 emissions or radiological risk. For us, as a builder, it is a matter of great pride to have laid the cornerstone of a structure of such importance to humanity.” said Jérôme Stubler, Chairman of VINCI Construction.

1The consortium in charge of construction of the main ITER buildings is led by VINCI via its subsidiaries VINCI Construction Grands Projets, VINCI Construction France and Dodin Campenon Bernard. It also includes the Ferrovial (Spain) and Razel-Bec (France) companies. The heavy nuclear doors were designed and produced by a VINCI Énergies subsidiary, Cegelec, in partnership with Sommer (Germany).

2A tokamak is an experimental machine designed to exploit fusion energy. In a tokamak, three conditions must be met to obtain a fusion reaction: very high temperature (about 150 million degrees Celsius); sufficient particle density to produce a very large number of possible collisions; and sufficiently long energy confinement time to ensure that the collisions occur at the highest possible speed. Tokamak is a Russian acronym standing for “toroidal chamber with magnetic coils”.

3The plasma, the fourth state of matter, is achieved when a gas is raised to a very high temperature, dissociating electrons and nuclei. In this medium, hydrogen nuclei can fuse and release energy.

The joint venture will be responsible for the final design, construction and commissioning of Old Oak Common station in North West London, delivering six underground platforms as well as up to eight platforms on the adjacent Great Western Main Line.

Balfour Beatty’s in-depth expertise of constructing critical major transport terminals across the world will combine with VINCI’s knowledge in constructing high speed lines and UK rail infrastructure projects, and SYSTRA’s expertise in designing, integrating and project managing transport systems.

On completion, Old Oak Common station will become the UK’s best-connected station, providing direct services to three major airports, eight of Britain’s ten largest cities and forming part of one of Britain’s largest regeneration projects which will help create up to 65,000 jobs and 25,000 new homes in West London while also dramatically increasing rail capacity across the UK.

Nigel Russell, Project Director for the Balfour Beatty VINCI SYSTRA joint venture said: “This award reflects the combined strength of our joint venture and recognises our world-class capabilities in designing, managing and delivering complex infrastructure projects.

“We look forward to applying our expertise to deliver this critical piece of national infrastructure so essential to driving the skills agenda, to the rebalancing of the UK economy and to the enabling of a resilient and competitive construction and infrastructure industry.”

At construction peak the project will employ a direct management team of 140 and a wider workforce of approximately 2,500.

This latest contract award follows Balfour Beatty VINCI’s appointment in 2017 to deliver Lot N1 and Lot N2 of HS2’s main civil engineering works package in a two-part design and build contract, valued at c. £2.5 billion.

On Friday, 2 August 2019, Panamanian President, Laurentino Cortizo, and Panama Canal Administrator, Jorge Quijano, unveiled the Atlantic Bridge in Colón, Panama. This exceptional 4.6 km structure, including 3.1 km of exceptional engineering structures, located 3 km north of the Gatun and Agua Clara locks, creates a new link between the North American and South American continents that can be used whether the canal locks are in operation or not.

Due to the adversity of the Panamanian tropical climate on the Atlantic side, a technical solution entirely made of reinforced concrete was chosen by the Panama Canal Authority rather than a metal structure. The central span (the bridge section that spans the canal), consisting of 530 metres of concrete deck located 75 metres above sea level, constitutes a world record for a cable-stayed bridge, while its two towers dominate the waters of the Atlantic Ocean at over 210 metres high. The foundations of these towers, anchored in highly unstable ground subject to potentially major seismic disturbances, posed a veritable challenge.

In order for work to be carried out without interrupting the transit of container ships, four innovative form travellers, each weighing 240 tonnes, were used to build the central span.

Thanks to a strong and shared safety culture during the design and construction of this unique engineering structure, it was completed without any serious accidents.

The construction of this bridge relied heavily on the Group’s expertise in synergy: VINCI Construction Grands Projets built the infrastructure, Rodio Swissboring Panamá, subsidiary of Soletanche Bachy, created the deep foundations and Freyssinet installed the stays.