BACKGROUND

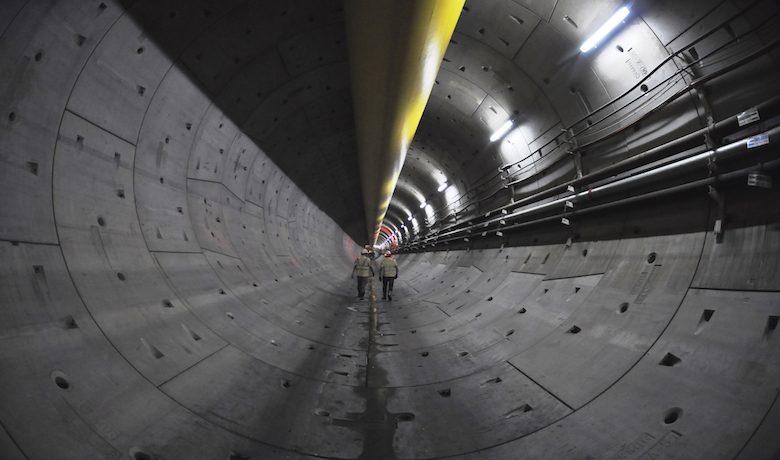

Hong Kong, which is China’s fifth-most populated city and ranks among the world’s most densely populated urban areas, is currently experiencing a new phase of infrastructure development. The city’s first metro line was opened in 1910. Today, the network encompasses no fewer than 9 metro lines, an express line servicing the airport, and a Light Rail Transit (LRT) system. To accommodate increasing passenger traffic in Hong Kong, the local government announced in 2009 that it would invest in expanding the rail network as part of the Hong Kong 2020 program, which also aims to reduce greenhouse gas emissions in this major metropolis. In addition, this new project is designed to link the island of Hong Kong with the New Territories (which represent more than 80% of the surface area of Hong Kong and are home to more than half of its population).